The industry of Reeling Machines is evolving rapidly. According to John Smith, a leading expert in this field, “Innovation drives efficiency.” With advancements in technology, the Reeling Machine is becoming smarter and more efficient.

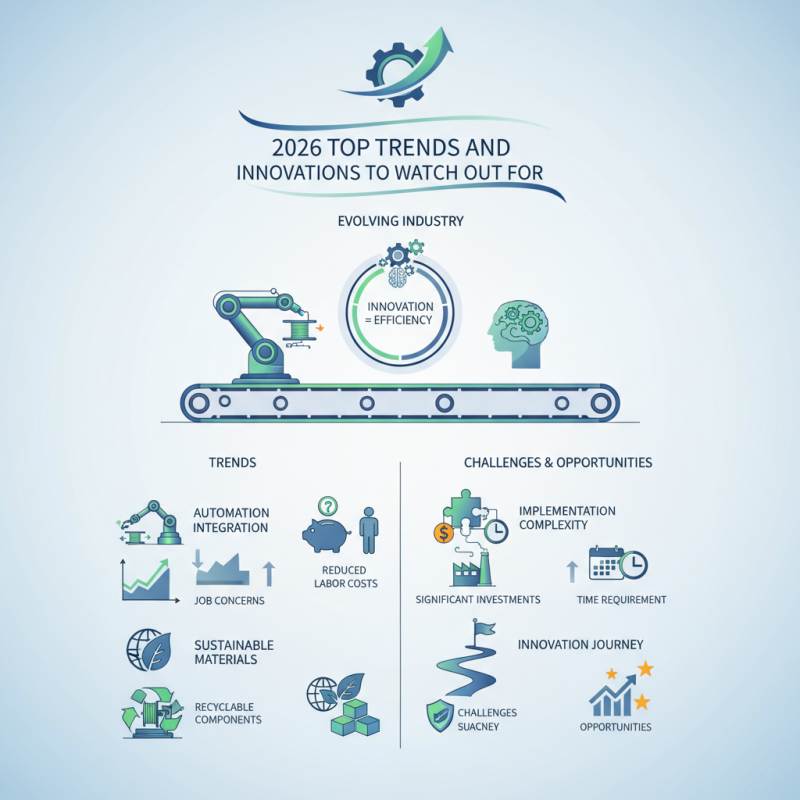

One notable trend is the integration of automation. Machines can now operate with minimal human intervention. This shift reduces labor costs but raises concerns about job displacement.

Another exciting development is the use of sustainable materials. In a world increasingly focused on eco-friendliness, Reeling Machines made with recyclable components are on the rise. Nevertheless, implementing these changes can be complex, requiring significant investments and time. The journey towards innovation in the Reeling Machine sector is full of challenges and opportunities.

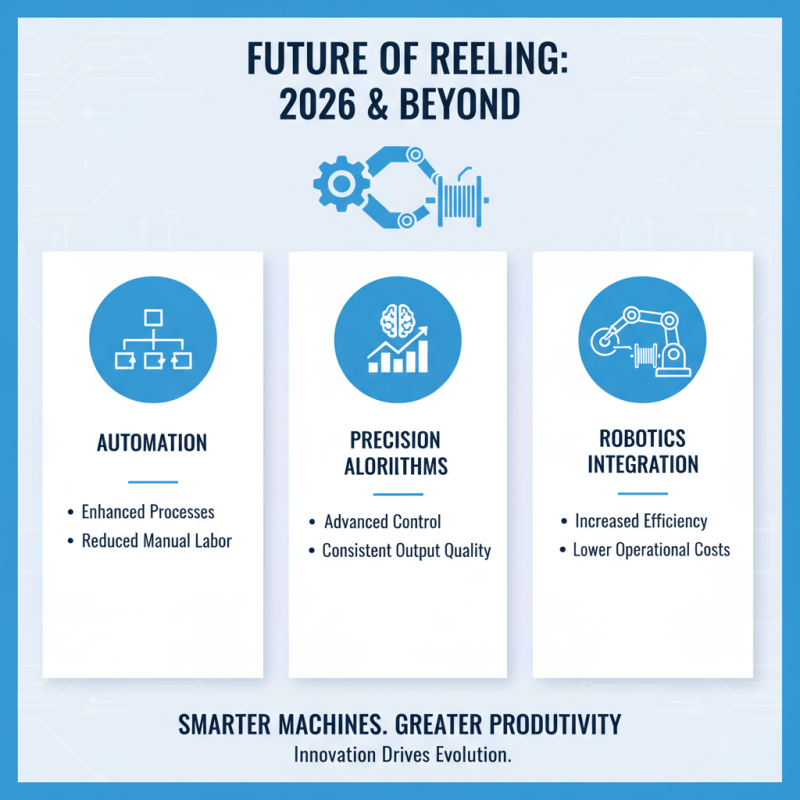

Reeling machines are evolving rapidly due to innovations in technology. In 2026, we can expect to see more automation in reeling processes. These machines will rely on sophisticated algorithms for enhanced precision. Robotics will play a significant role in increasing efficiency. This could reduce labor costs and improve productivity.

Another interesting trend is the integration of IoT technology. Reeling machines will become smarter. These machines can communicate data in real-time. This allows for better monitoring and maintenance. By analyzing performance metrics, manufacturers can refine their processes. However, the implementation of such technologies may pose challenges. Training staff to operate these advanced machines will be crucial.

Sustainable practices are also emerging. Companies will seek to reduce waste in the reeling process. This might involve the use of eco-friendly materials. However, the transition may not be seamless. Some facilities may struggle to adapt to these changes. Addressing these issues requires careful planning and consideration. As we move towards 2026, focusing on embracing innovation while being mindful of these challenges will be key.

As the demand for sustainable practices grows, the reeling machine industry is evolving. Manufacturers are exploring eco-friendly materials and energy-efficient designs. Innovations now include machines that reduce waste and use renewable energy sources. Processes are being streamlined to lessen environmental impact. This shift toward sustainability is not merely a trend but a necessity for the industry’s future.

However, challenges exist. Transitioning to sustainable practices can be costly. Many companies struggle to balance performance and eco-friendliness. Recycling old machines is another hurdle; it requires infrastructure and commitment. Education on sustainability for workers and operators is also crucial. Without proper training, the effectiveness of sustainable innovations can falter.

Creating a greener industry is an ongoing process. Stakeholders must collaborate more to share best practices. There is a need for continuous reflection on methods and materials used in manufacturing. The industry has a long way to go but is making strides in the right direction.

| Trend/Innovation | Description | Impact on Sustainability | Expected Adoption Rate (%) |

|---|---|---|---|

| Eco-Friendly Materials | Increasing use of biodegradable or recyclable materials for machine components. | Reduces plastic waste and carbon footprint. | 75% |

| Energy-efficient Motors | Integration of advanced energy-efficient motors to decrease power consumption. | Lower energy consumption leads to reduced greenhouse gas emissions. | 68% |

| Automation and AI | Leveraging AI for predictive maintenance and optimization of reeling processes. | Improves efficiency and reduces waste in manufacturing processes. | 60% |

| Smart Reeling Technology | Implementation of IoT solutions for real-time monitoring and control. | Enables resource optimization and reduces downtime. | 80% |

| Closed-Loop Systems | Adoption of closed-loop systems for waste reduction in production cycles. | Minimizes waste generation and enhances resource efficiency. | 70% |

The future of reeling machines is bright, especially with innovative materials and design approaches. Lightweight composites are gaining popularity. These materials enhance machine efficiency without sacrificing durability. Imagine a reeling machine that is much easier to transport and operate. The reduction in weight has the potential to revolutionize how these machines are used in various industries.

On the design front, minimalistic approaches are becoming more common. Streamlined designs not only look modern but also improve functionality. Fewer parts often mean less maintenance. However, this can lead to challenges in repairs. When a part fails, replacement may become more complicated, requiring specialized skills. It’s vital to strike a balance between innovation and practicality.

The implementation of smart technology is also a hot topic. Sensors integrated into reeling machines can monitor performance in real time. This provides valuable data for optimization. Yet, reliance on technology raises concerns. What happens if the system fails? Understanding these vulnerabilities is crucial for moving forward. Balancing innovation with reliability will be key in the evolution of reeling machines.

In the realm of modern manufacturing, automation is revolutionizing reeling machines. Smart features enable these machines to tune themselves to specific tasks. This adaptability reduces human error and ensures precision in every wind. Many facilities are adopting these innovations to enhance efficiency. Workers are often amazed by how much more can be accomplished with less manual effort.

Data-driven insights play a crucial role in these advanced machines. Sensors gather information in real-time, allowing operators to make informed decisions. This technology not only boosts productivity but also highlights areas for improvement. Downtime can be minimized with predictive maintenance features. However, this reliance on data raises questions about cybersecurity risks. Protecting sensitive information is now a critical challenge in automation.

Moreover, the integration of AI can be a double-edged sword. While it often yields remarkable results, it may also lead to unforeseen complications. The learning curve for employees can be steep, requiring continuous training. Balancing innovation with human skill remains a prevalent concern. As the industry evolves, manufacturers must critically assess the implications of these technologies.

The reeling machine industry is shaped by several market dynamics in 2026. Technological advancements are driving efficiency. Automation enhances productivity and reduces labor costs. Companies are investing in smart machinery that integrates IoT. This helps monitor performance in real-time. Efficiency is not just about speed; it includes energy consumption and waste reduction.

Sustainability is another crucial factor. Many businesses are seeking eco-friendly materials and processes. Consumers demand greener options, pushing companies to adapt. This shift leads to innovation but also challenges. Some manufacturers struggle with balancing cost and sustainability. As regulations on emissions tighten, adapting becomes essential. These market pressures may lead to increased competition.

Global supply chain fluctuations also impact trends. With uncertainties in sourcing, many seek local suppliers. This change promotes regional manufacturing but can lead to higher costs. It requires careful planning and risk assessment. Companies must pivot to maintain their market shares. Navigating these dynamics is complex and requires constant reflection and adaptation.