In today's fast-paced industrial world, the Tensioner Machine plays a critical role across various sectors. Reports indicate that using mechanized tensioning equipment can enhance efficiency by up to 30%. This figure is significant, particularly in manufacturing and construction. Utilizing these machines minimizes manual labor and reduces time spent in projects.

Many industries benefit from the precision of a Tensioner Machine. For instance, in the automotive sector, accurate tensioning of components directly affects vehicle safety. Approximately 20% of mechanical failures are due to inadequate tensioning. These failures can be avoided with better technology. Despite its advantages, the adoption of tensioner machines requires initial investment and training.

Industry leaders recognize the need for innovation. Upgrading to advanced tensioning systems can lead to a competitive edge. However, organizations must evaluate the potential drawbacks. Transitioning from manual practices can encounter resistance. Addressing this cultural shift is crucial for long-term success. Overall, the integration of tensioning machines is a worthwhile consideration for enhancing productivity and safety in various industries.

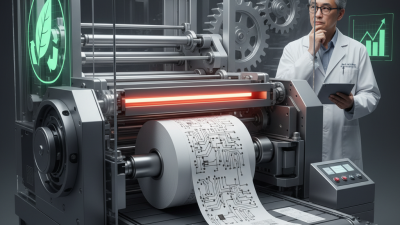

Tensioner machines have become indispensable in various industries due to their ability to enhance efficiency significantly. In manufacturing, for instance, studies suggest that integrating tensioner technology can boost productivity by up to 30%. This is achieved by ensuring that materials are handled with optimal tension, reducing waste and improving output quality. The automotive sector, particularly, sees fewer defects from parts that are consistently tensioned, leading to savings on rework.

Tips: Regular maintenance of your tensioner machine ensures consistent performance. It can prevent unexpected downtimes that often lead to inefficiencies.

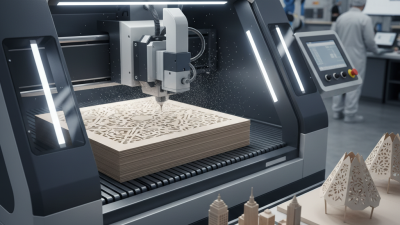

In sectors like construction and telecommunications, accurate tension control is vital. Reports indicate that projects utilizing tensioning solutions finish 25% faster than those relying on manual techniques. This speed translates to lower labor costs and quicker project turnover. However, not all implementations are seamless. Companies must be cautious about the calibration of these machines. Inaccurate settings can lead to over-tensioning, causing material failure.

Tips: Always re-evaluate tension settings if excessive wear appears on materials. This can save both time and resources.

Using a tensioner machine can significantly enhance quality control in manufacturing processes. Tensioners ensure that materials are consistently held at the correct tension. This precision prevents defects that could arise from slack or tightness in production lines. When tension is uniform, products become more reliable and durable. Consequently, businesses see fewer returns and complaints, ultimately boosting customer satisfaction.

Tips: Regularly inspect your tensioner machine. Any wear and tear can lead to inconsistencies. A periodic maintenance schedule is essential. Also, train staff on proper usage. Untrained hands can make simple mistakes that compromise quality.

Monitoring tension in real-time provides immediate feedback. If something goes wrong, adjustments can be made instantly. This proactive approach helps maintain production flow. However, companies must acknowledge that achieving perfect tension is a process. It may require trial and error to find the ideal settings. Frequent testing of materials ensures optimal performance and minimizes defects.

Tensioner machines play a crucial role in various industries by improving efficiency and reducing costs. By automating tensioning tasks, these machines minimize manual labor and the likelihood of human error. This leads to more consistent results and fewer product defects. As a result, companies can allocate resources effectively, ensuring that every dollar is well spent.

Implementing tensioners often results in significant material savings. The precise control they offer helps prevent overuse of raw materials. This means companies can lower waste and optimize their production processes. Moreover, adjusting production parameters becomes much simpler. The initial investment can be perceived as steep, but the long-term savings usually outweigh this concern.

Tips: Start small when integrating tensioners. Monitor performance and review potential adjustments regularly. Analyze how the introduction of tensioners impacts overall production flow. Engaging employees in this transition can also yield insights you might miss alone. Remember, each industry is unique; adjust your approach accordingly.

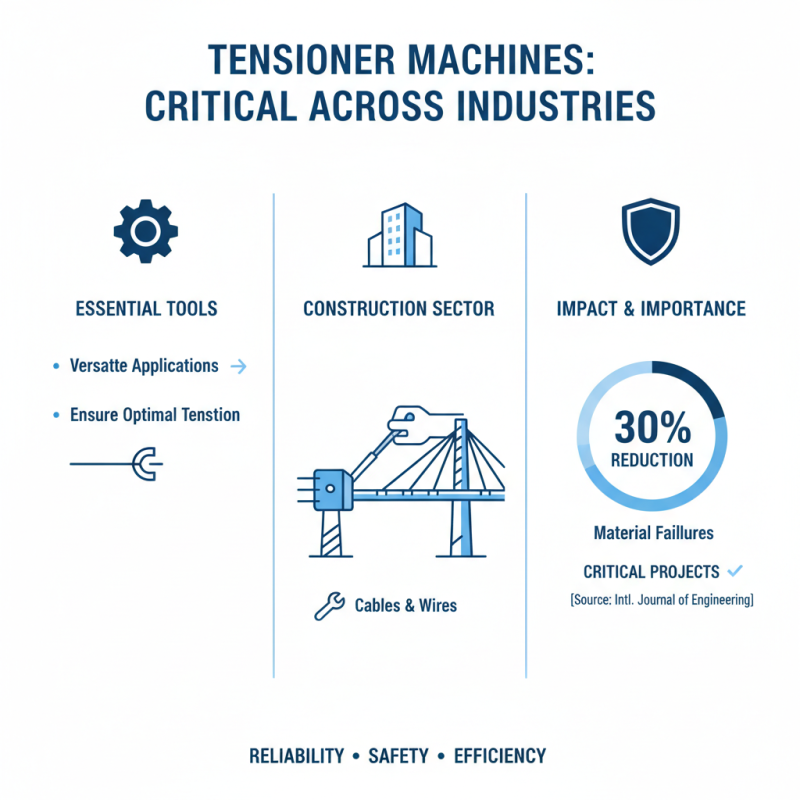

Tensioner machines are essential tools across various industries. Their versatility allows them to adapt to diverse applications. For instance, the construction sector frequently employs these machines to ensure the optimal tension of cables and wires. According to a report from the International Journal of Engineering, proper tensioning can reduce material failures by 30%. This emphasizes the importance of using tensioners in critical projects.

In the automotive industry, tensioners assist in maintaining the proper tension of belts and hoses. This is vital for vehicle performance and safety. A study by the National Automotive Engineers found that improper tension can lead to a 15% decrease in fuel efficiency. Clearly, the right tensioning technology impacts not only performance but also environmental sustainability.

However, not all tensioner machines have the same capabilities. Some may lack precision and require constant recalibration. This could lead to inefficiencies and costly downtime. Industries must evaluate their needs carefully. Investing in more advanced technology may seem burdensome, yet it could ultimately save time and resources. Balancing cost and functionality remains a challenge for many sectors today.

The integration of tensioner machines in various industries has notably improved safety operations. According to a recent industry report, improper tensioning accounts for up to 30% of equipment failures. When utilizing advanced tensioner technology, the potential for human error decreases significantly. These machines provide precise control, ensuring cables and belts are tightened to the ideal specifications. As a result, the likelihood of accidents diminishes.

Additionally, tensioner machines reduce the risk of injuries in workplaces. A study by the Occupational Safety and Health Administration (OSHA) revealed that workplaces using tensioning technology experienced a 25% reduction in injury reports. Employees enjoy safer handling processes, which is crucial in heavy industries like construction and manufacturing. However, challenges remain. Not all operators are trained effectively, which can lead to unsafe practices. This gap needs addressing to realize technology's full safety potential.

In sectors such as automotive or aerospace, where precision is critical, tensioners help maintain structural integrity. This not only protects workers but also ensures product longevity. The initial investment in these machines is significant, yet companies must reflect on the greater returns in safety and efficiency. Safety advancements using tensioner technology are clear, but ongoing training and evaluation will be vital in harnessing their full benefits.

The graph above illustrates the top 10 benefits of using tensioner machines across different industries, showcasing their significant positive impacts on safety, efficiency, and cost-effectiveness in operations.