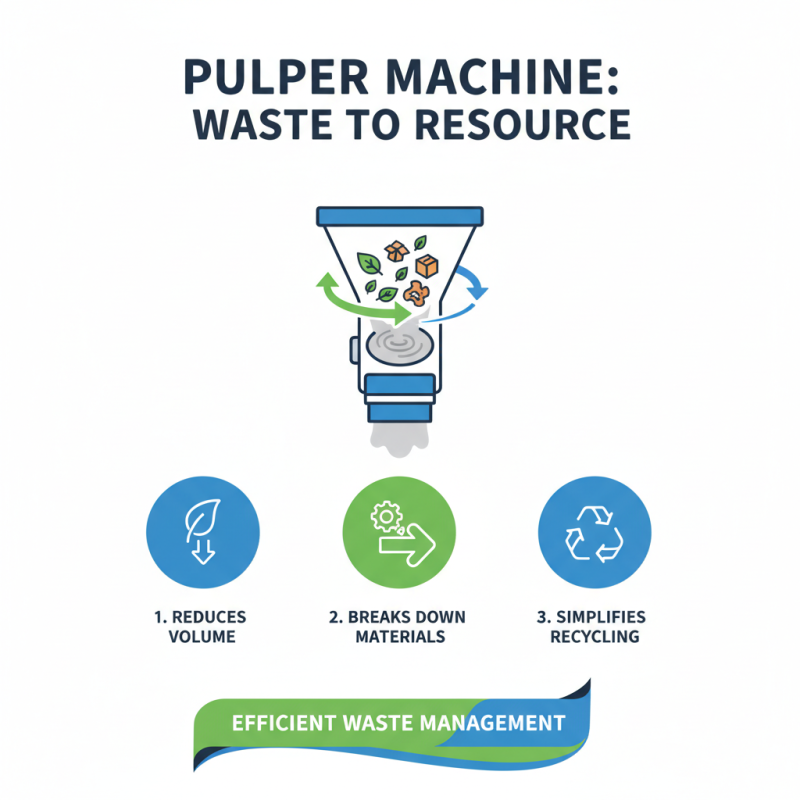

In today's world, efficient waste management is crucial. The "Pulper Machine" stands out in this field. According to Dr. Emily Harper, an expert in waste recycling technologies, "A Pulper Machine can revolutionize the approach to waste handling." This statement emphasizes the innovative potential of this machinery.

Pulping machines play a significant role in reducing waste volume. They transform various materials into pulp, making recycling easier. With improved technology, the efficiency of these machines continues to grow. However, not all businesses leverage their full potential. Some may overlook maintenance, leading to inefficiencies.

Moreover, implementing a Pulper Machine can be a significant upfront investment. Companies need to weigh the costs against long-term benefits. Misunderstandings about its operation can also hinder optimal usage. Nonetheless, when used correctly, a Pulper Machine offers substantial advantages in waste management practices.

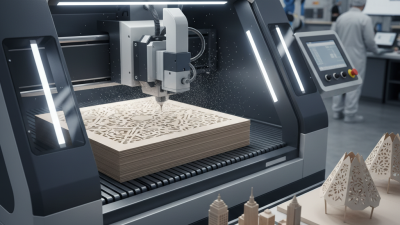

A pulper machine is a vital tool for efficient waste management. It transforms organic materials into pulp, simplifying recycling processes. This machine effectively reduces the volume of waste. By breaking down materials, it prepares them for further processing. The result is a more manageable waste stream.

Using a pulper can enhance waste sorting. It separates different types of materials, making recycling easier. This improves the overall efficiency of waste management systems. However, operators must be trained to use these machines properly. Improper use can lead to downtime and increase costs.

While pulpers offer great benefits, they can also pose challenges. Regular maintenance is crucial to ensure optimal performance. Neglecting maintenance can lead to malfunctions. Identifying and resolving issues takes time. For companies, balancing maintenance and daily operations can be tough. Using a pulper requires careful planning, but the long-term efficiency gains are significant.

Pulper machines play a crucial role in enhancing waste reduction efficiency. They effectively process materials like paper and organic waste. This transformation cuts down overall waste volume significantly. A pulper breaks down the feedstock into digestible pulp. This process makes recycling and repurposing much easier for businesses and individuals.

Implementing a pulper machine can seem complex at first. However, it can lead to impressive results in waste management. When waste is reduced, disposal costs typically go down. More importantly, it helps in minimizing the environmental footprint. Individuals should consider the compatibility of their pulping needs with their current waste stream.

Tips: Regular maintenance is essential for optimal performance. Ensure the machine is clean and functioning correctly. Monitoring input quality can also improve efficiency. Analyzing waste streams can help identify areas for better reduction. Remember, it's not about perfection; it's about progress in waste management. Every small improvement counts.

Pulper technology presents significant environmental benefits for waste management. The implementation of pulper machines can drastically reduce the volume of waste generated. According to a report by the Environmental Protection Agency (EPA), recycling and pulping can decrease landfill mass by up to 30%. This reduction is essential as landfills contribute to soil and water pollution.

Furthermore, pulper machines process organic materials effectively. They reclaim valuable resources like paper pulp, which can be repurposed into new products. The recycling process reduces the need for virgin materials. A study from the Paper Recycling Association states that recycling one ton of paper saves around 24,000 gallons of water and significantly lowers greenhouse gas emissions.

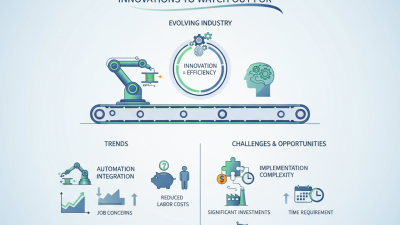

However, adopting pulper technology isn't without challenges. Some facilities struggle with initial costs and maintenance. Training staff can also pose difficulties. Continuous improvement in these areas is crucial to maximizing the benefits of pulper machines. The waste management industry must address these obstacles to fully realize the potential of pulper technology.

Industries are increasingly adopting pulper machines for waste management. These devices make recycling more efficient. Data shows that using a pulper can reduce waste by up to 50%. This reduction translates into lower disposal costs. Facilities save money on landfill fees and manage waste better.

Moreover, pulper machines can improve resource recovery rates. A report by Waste Management World states that pulpers can increase pulp recovery by 25%. This statistic highlights the machines' ability to process raw materials effectively. Industries reduce their environmental footprint significantly. However, implementing these machines requires initial investment and workforce training, which some companies may find challenging.

The long-term savings often outweigh these upfront costs. Pulper machines can enhance production efficiency. Reports indicate that companies using pulpers often see a 15% reduction in raw material consumption. This efficiency gain contributes to overall operational cost savings. Yet, not every organization integrates these systems seamlessly. Some face operational hurdles, suggesting a need for careful planning and strategy.

| Benefit | Description | Economic Impact |

|---|---|---|

| Reduced Waste Volume | Pulper machines efficiently reduce the volume of waste, making it easier to manage and transport. | Lower disposal costs due to decreased waste volume. |

| Resource Recovery | Allows recovery of valuable materials from waste, turning trash into reusable resources. | Increased revenue from selling recovered materials. |

| Energy Efficiency | Optimizes energy consumption during waste processing. | Reduced energy costs leading to lower operational expenses. |

| Environmental Compliance | Helps industries comply with environmental regulations by minimizing waste impact. | Avoidance of fines and penalties related to waste management regulations. |

| Process Simplification | Streamlines waste processing workflows in various industries. | Increased productivity and reduced labor costs. |

Pulper machines are versatile tools found in various industries. Their primary application lies in the recycling of waste materials. These machines efficiently break down paper and other organic waste into usable pulp. In the food processing sector, they help manage fruit and vegetable scraps, turning these waste products into valuable compost or biofuel.

In the packaging industry, pulper machines play a crucial role in waste management. They streamline the recycling process for cardboard and paper materials. By reducing the volume of waste, businesses can cut costs and minimize their environmental impact. However, the effectiveness of these machines depends on proper operation and maintenance. Regular checks are necessary to ensure optimal performance.

The textile industry also benefits from pulper technology. It helps process fabric waste, which can be challenging to recycle. Many companies are still figuring out the best methods for utilizing pulper machines in this sector. There is potential for improvement in waste management practices, ensuring that valuable resources are not lost.

The following chart illustrates the various benefits of using pulper machines in waste management, including efficiency, cost savings, environmental impact, and versatility across different sectors.