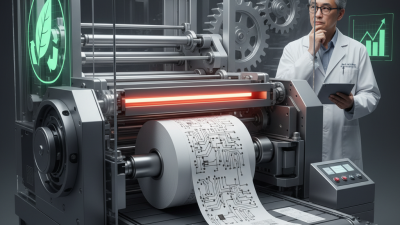

The increasing demand for precision crafting and efficient production has highlighted the significance of the Paper CNC Machine. According to a recent industry report by MarketsandMarkets, the global CNC machine market is expected to grow from $66 billion in 2021 to $100 billion by 2026, reflecting a compound annual growth rate of 8.5%. This surge emphasizes the need for advanced equipment like the Paper CNC Machine, which provides both accuracy and speed in manufacturing processes.

Scott Jenkins, a CNC technology expert, states, "The Paper CNC Machine revolutionizes traditional crafting methods, ensuring minimal waste and maximum efficiency." As industries strive for improvement, it’s essential to recognize that not all CNC machines deliver consistent quality. The selection of a reliable Paper CNC Machine can significantly impact production outcomes. There’s still room for innovation, and users must remain vigilant in assessing their machinery. Every detail matters in precision crafting; overlooking potential shortcomings could lead to losses.

In this ever-evolving landscape, manufacturers are urged to invest wisely in technology. By focusing on the right Paper CNC Machine, companies can achieve remarkable results. Yet, it is crucial to balance technological advancements with practical applications. Adapting to change is key, but one must always reflect on how machinery performs in real-world scenarios.

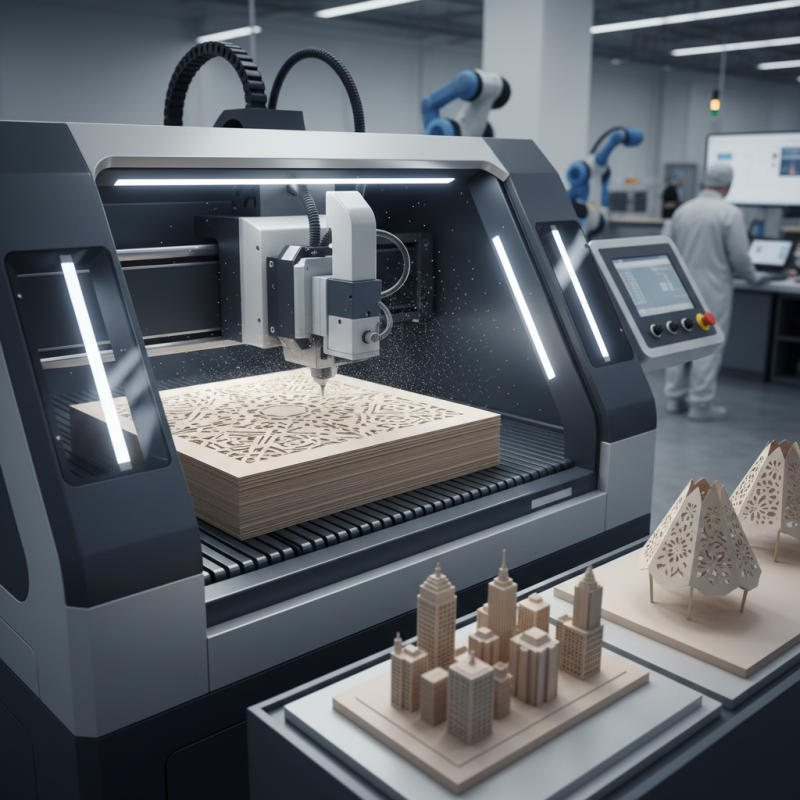

When selecting a CNC machine for precision crafting in 2026, consider the key features essential for your projects. A machine with a high-resolution spindle can greatly enhance detail. Look for a spindle speed that allows for a broad range of materials. Flexibility in material handling is also critical. A versatile CNC machine will accommodate wood, metal, and plastics.

Don't overlook the importance of software compatibility. An intuitive interface can make a significant difference in usability. Be cautious; some machinery comes with overly complex software that might frustrate operators. Additionally, check the accuracy rating of the machine. A tolerance of ±0.01 mm is impressive, but much depends on your application.

Also, consider the size and workspace of the machine. It should fit within your designated area without compromising functionality. Remember, larger machines can sometimes be cumbersome. Reflecting on your specific needs is vital. The best machine is not always the most advanced one; sometimes, simplicity leads to better results. Each project will demand different features, so choose wisely based on what matters most to you.

In 2026, the competition among CNC machine brands is fierce. Companies are pushing boundaries in precision crafting and production efficiency. Many machines now come with advanced features like adaptive controls and intuitive interfaces. These enhance user experiences, making precision work more accessible. However, some brands still struggle with consistency in quality. Users often report issues with calibration, leading to frustration.

When comparing leading brands, it’s essential to consider reliability. Some machines are engineered for heavy-duty tasks and can handle various materials, including metals and woods. Yet, others may perform well with soft materials but falter under pressure. These differences can impact production flow significantly. Not all CNC machines are user-friendly; navigating complex software can be daunting. It’s an area where many brands can improve.

Additionally, the energy efficiency of these machines is crucial. With rising operational costs, brands that prioritize energy-saving features gain an edge. While some machines boast low power consumption, others may not deliver the promised savings. This discrepancy needs thoughtful evaluation. Overall, selecting the right CNC machine requires careful consideration of these essential factors. It's not just about the latest technology; real-world performance is what counts.

| Model | Max Cutting Speed (mm/min) | Max Precision (mm) | Material Types | Price Range ($) | Warranty Period (Years) |

|---|---|---|---|---|---|

| CNC Model A | 12000 | 0.02 | Wood, Metal, Plastic | 3000 - 5000 | 2 |

| CNC Model B | 15000 | 0.015 | Aluminum, Plastic | 4000 - 6000 | 3 |

| CNC Model C | 10000 | 0.03 | Wood, Composite | 2500 - 4500 | 1 |

| CNC Model D | 18000 | 0.01 | Metal, Wood, Leather | 5000 - 8000 | 4 |

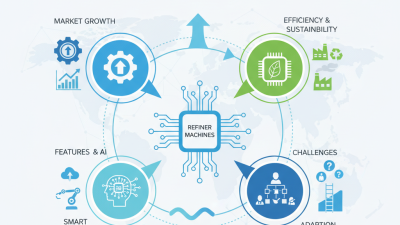

Innovative technologies in CNC machines are revolutionizing crafting applications. With advancements in software and hardware, precision and speed are significantly improved. Modern CNC machines now feature enhanced sensors and automated calibration. These tools can adapt to varying materials and complex designs, offering users greater flexibility.

Cutting-edge features include integrated AI systems. These systems help optimize cutting paths, reducing waste and time. Yet, challenges remain. For instance, not all operators grasp the software, which can lead to errors. Additionally, the cost of these machines can be prohibitive for smaller workshops.

Real-time data monitoring is crucial. It allows for instant feedback on performance and issues. However, understanding this data requires training. Mistakes can happen if operators are not experienced. Tuning these machines for specific tasks may also require trial and error. This highlights the need for continuous education and improvement in CNC technology.

The CNC machine market is evolving rapidly in 2026. Companies seek cost-effectiveness more than ever. A recent industry report indicates that CNC machines can boost production efficiency by up to 30%. This level of increase can significantly lower operational costs in the long term. Investing wisely in these machines may seem daunting. However, their functionality often outweighs initial expenses.

When considering return on investment (ROI), it's crucial to analyze long-term benefits. Many manufacturers report that their ROI within the first year is around 150%. This is a compelling argument for CNC adoption. Yet, not all machines deliver the same value. Some may lack features that enhance precision and speed. Users need to evaluate their unique needs carefully.

Moreover, maintenance costs can erode savings quickly. Regular upkeep is essential to avoid downtime. Companies need to factor these costs into their budget. Smart investment in technology helps, but it requires thought. The ultimate aim is to find machines that balance performance and affordability. This involves continuous learning and adjustments as technology evolves.

This bar chart showcases the estimated cost-effectiveness and value of investment in CNC machines for precision crafting and efficient production in 2026.

Maintaining precision in CNC operations is crucial for optimal performance. Regular maintenance routines can prevent unexpected breakdowns. Inspecting machine components frequently is essential. Take time to clean the parts and check for wear. Over time, minor issues can become significant. It’s vital to address them early.

Calibration is another key aspect of precision. A system that isn’t properly calibrated can produce flawed outputs. Operators should perform calibration checks at regular intervals. This helps ensure that measurements are accurate. It might seem tedious, but the effort pays off in quality results. Neglecting this can lead to costly reworks.

Documentation plays a crucial role in maintaining CNC machines. Keeping records of maintenance activities assists in identifying patterns. Over time, these insights can improve both efficiency and precision. It's easy to overlook this step, but it's important to reflect on its value. Regularly updating logs can create a clearer picture of machine health.