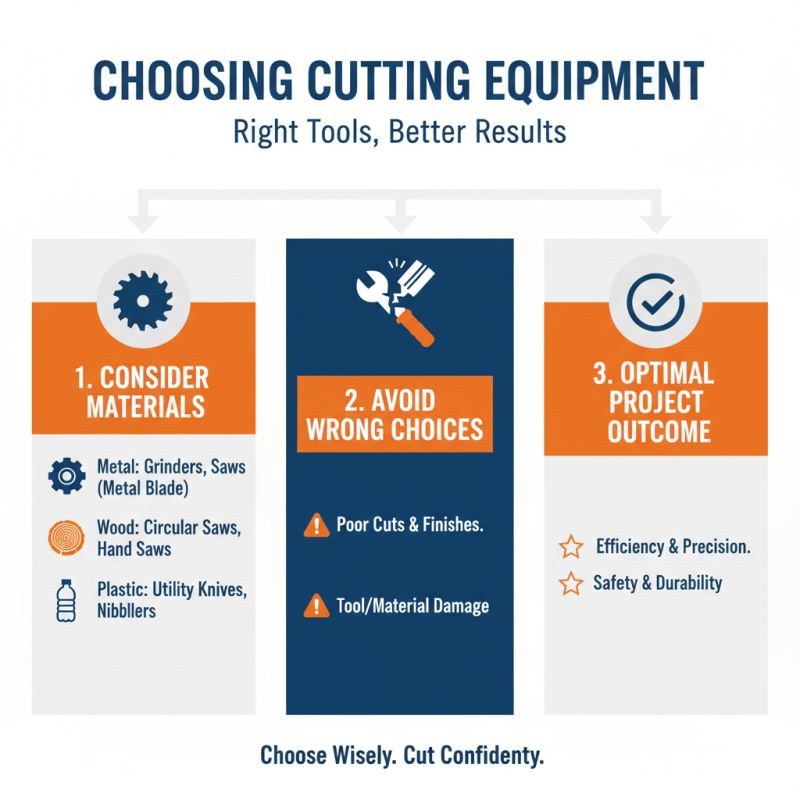

Choosing the right cutting equipment is vital for any project. According to Gary Thompson, a leading expert in the cutting equipment industry, “The right tool can transform your work efficiency.” Selecting appropriate tools can minimize errors and enhance results.

When considering cutting equipment, factors like material type, project size, and budget play a crucial role. For instance, a project involving delicate materials requires precision tools. It's easy to overlook compatibility or functionality. This might lead to poor outcomes and unnecessary costs.

Remember, not all cutting equipment suits every task. You may face setbacks or frustrations if you choose hastily. Reflecting on previous experiences can guide your decision-making process. Making thoughtful choices is essential for achieving your project goals.

Choosing the right cutting equipment is crucial for any project. Different materials require specific tools. For instance, metals typically demand saws or plasma cutters. A recent industry report suggests that the metal cutting tools market is expected to reach $5.9 billion by 2027. This significant growth reflects the increasing demand for precision in metal fabrication.

Woodworking, on the other hand, has different requirements. For softwoods, a simple hand saw may suffice. However, hardwood demands more sophisticated equipment like band saws or table saws. Interestingly, surveys indicate that many woodworkers underestimate the impact of blade selection. Using an inappropriate blade can hinder performance and waste time.

For cutting plastics, specialized equipment is vital. Using standard tools can lead to melting and distortion. The global market for plastic cutting tools is projected to grow steadily, reflecting advancements in technology. Yet, some users still rely on outdated methods. It's essential to reevaluate techniques regularly. A mismatch between tool and material can lead to not just poor results, but also safety hazards.

Choosing the right cutting equipment is crucial for any project. First, consider the materials you will be cutting. Different materials require different tools. For instance, metal, wood, and plastic all need specific types of blades or cutters. A wrong choice can lead to poor results. It might even damage the tool or the material itself.

Next, think about the precision required for your work. For intricate cuts, a fine-toothed saw or a laser cutter may be necessary. For larger projects with basic cuts, a heavier-duty saw could suffice. Don’t underestimate the importance of sharpness either. Dull blades make cutting difficult and can compromise safety.

Also, reflect on your skill level and comfort with various tools. Some equipment requires advanced techniques, and using them can be challenging for beginners. Remember, safety is key. Always wear protective gear to avoid injuries. It’s worthwhile to practice with different tools before committing to a project. This exploration may reveal preferences you didn't know you had.

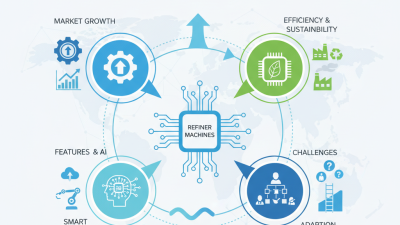

When selecting cutting equipment, understanding the benefits and limitations of various techniques is crucial. For instance, mechanical cutting is precise and efficient. However, it may not handle complex shapes well. This method excels in consistency but can struggle with delicate materials. It often generates heat, which can affect both the tool and the material.

On the other hand, laser cutting offers exceptional detail. It works well with intricate designs and thinner materials. Still, it can be expensive and requires skilled operators. Additionally, it produces fumes that may necessitate proper ventilation. Waterjet cutting presents a thrilling alternative. It uses high-pressure water, creating clean cuts without heat. This method is gentle on the material but may be slower compared to mechanical cutting.

Each technique has its trade-offs. Choosing the right equipment requires careful consideration. Think about the project's demands. Reflect on the materials involved and the desired outcome. The best choice is not always the most expensive one. It may be the one that fits the project's specific requirements.

Choosing the right cutting equipment involves understanding industry standards and safety guidelines. Safe practices are crucial for preventing accidents. According to the Occupational Safety and Health Administration (OSHA), over 200,000 injuries are reported annually in the construction sector due to improper equipment use. Following established protocols can significantly reduce these numbers.

Tip: Always inspect your equipment before use. Make sure all parts are functioning correctly. A small issue can lead to serious injuries.

Tip: Don't overlook the importance of a clean work area. Clutter can lead to accidents. Keeping the area organized helps everyone stay safe.

Despite following guidelines, mistakes can happen. It’s essential to reflect on past experiences and learn from them. Each project should be approached with a mindset of continuous improvement. Proper training and adherence to safety protocols can help create a safer work environment for everyone involved.

Estimating costs for cutting equipment can be tricky. You need to consider both the initial purchase price and the long-term consumables. These consumables can include blades, tips, and even safety gear. The selection of these items often influences overall project expenses. Not all equipment requires the same materials, so research is crucial.

Balance your budget between quality and necessity. Cheaper options may save money upfront, but they can lead to higher replacement costs later. Think about how often you will use the equipment. A high-quality tool may be a better investment for frequent tasks. Sometimes, it’s worth spending more now to ensure reliability and safety.

Don’t overlook maintenance costs either. Equipment needs care to perform effectively. Plan for spare parts and repairs in your budget. Unexpected breakdowns can quickly inflate your project costs. Keep a little extra in your budget for these unforeseen issues. Reflect on your choice of equipment regularly to remain efficient and cost-effective.