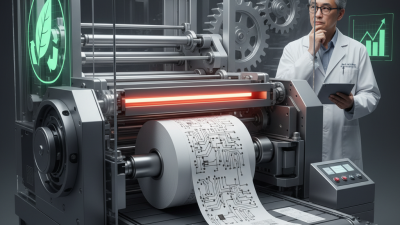

In the realm of modern engineering, the Reel Cylinder stands out as a crucial component. Dr. Emily Johnson, a renowned expert in mechanical systems, once stated, "The efficiency of modern machinery hinges on reliable components like the Reel Cylinder." This insight highlights its significance across various applications.

Manufacturers increasingly rely on the Reel Cylinder for its versatility. For instance, industries such as automotive and aerospace depend on its ability to provide smooth operations. The design integrates seamlessly into complex systems, enhancing overall performance. However, challenges persist. Quality control remains a concern, leading to inconsistencies in production.

Moreover, the adaptability of the Reel Cylinder invites continuous innovation. Engineers strive to improve its design to meet evolving demands. Yet, this pursuit occasionally overlooks the balance between cost and quality. Unchecked, it risks compromising performance. The Reel Cylinder truly represents a pivotal element in contemporary engineering, deserving ongoing exploration and assessment.

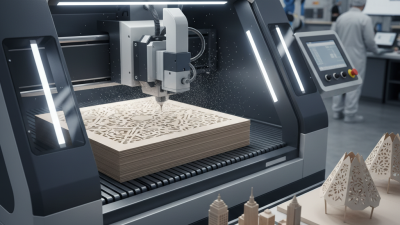

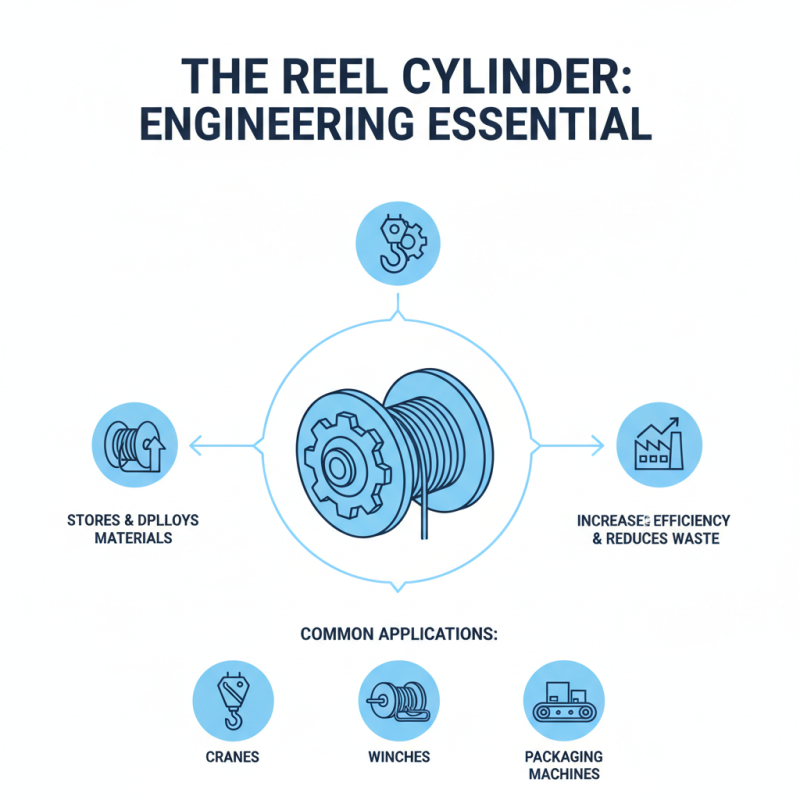

The reel cylinder plays a vital role in modern engineering. Its functionality transcends simple mechanical movement. It is designed to store, deploy, and retract materials smoothly. Engineers often utilize this mechanism in various applications like cranes, winches, and packaging machines. The controlled movement aids in efficiency, minimizing waste.

In terms of actual engineering practices, the reel cylinder is sometimes neglected. Not all engineers appreciate its potential. Some view it merely as a tool, rather than a key component of design. This mindset can hinder innovation. A deeper understanding of its functionality could inspire new approaches in machine design.

Moreover, real-world challenges often arise with reel cylinders. Issues like friction and wear can compromise performance. Creativity is needed to address these problems effectively. Engineers must reflect on their designs and consider adjustments. By doing so, they can enhance the longevity and functionality of the reel cylinder.

Reel cylinders play a crucial role in modern manufacturing processes. They are often used for material handling. In factories, they transport large spools of wire, cable, or fabric. This ensures efficient movement without tangles or breaks. Their design allows for smooth unwinding. This feature minimizes wear and tear during production.

In addition to material handling, reel cylinders are vital for automation. Many machines rely on them to feed materials continuously. This increases productivity and reduces manual labor. Their adaptability makes them suitable for various industries, from textiles to electronics.

Proper maintenance of reel cylinders is critical. Neglect can lead to disruptions in production.

Despite their importance, reel cylinders can have limitations. Sometimes, they struggle with heavier materials. Manufacturers need to assess their capacity carefully. Using the wrong cylinder can cause accidents. Regular evaluations of systems are necessary. This ensures safe and efficient operations in the long run.

Reel cylinders play a crucial role in modern engineering, particularly in material handling systems. They are designed to efficiently store and dispense various materials. This functionality simplifies the process and enhances productivity. With their streamlined design, they can minimize space while maximizing load capacity.

When using reel cylinders, consider weight distribution. Uneven loads can lead to equipment failure. Always ensure that the materials are evenly distributed for safe operation. A well-maintained reel cylinder can improve efficiency. Regular checks for wear and tear are necessary to avoid unexpected downtimes.

Using reel cylinders also promotes safety. They minimize the risk of injuries in the workplace. By using these tools, workers can manage materials without struggling. Simplifying this process is essential for maintaining a smooth workflow. However, training is vital. Operators must understand the correct usage and handling of these systems.

| Dimension | Benefits | Applications | Efficiency Rating |

|---|---|---|---|

| Load Capacity | Increased safety in material handling | Manufacturing | 95% |

| Ease of Use | Reduced operator fatigue | Logistics | 90% |

| Versatility | Adaptable to different materials | Construction | 92% |

| Durability | Long lifespan with minimal maintenance | Heavy Industry | 97% |

| Cost-Effectiveness | Lower operational costs | Retail | 89% |

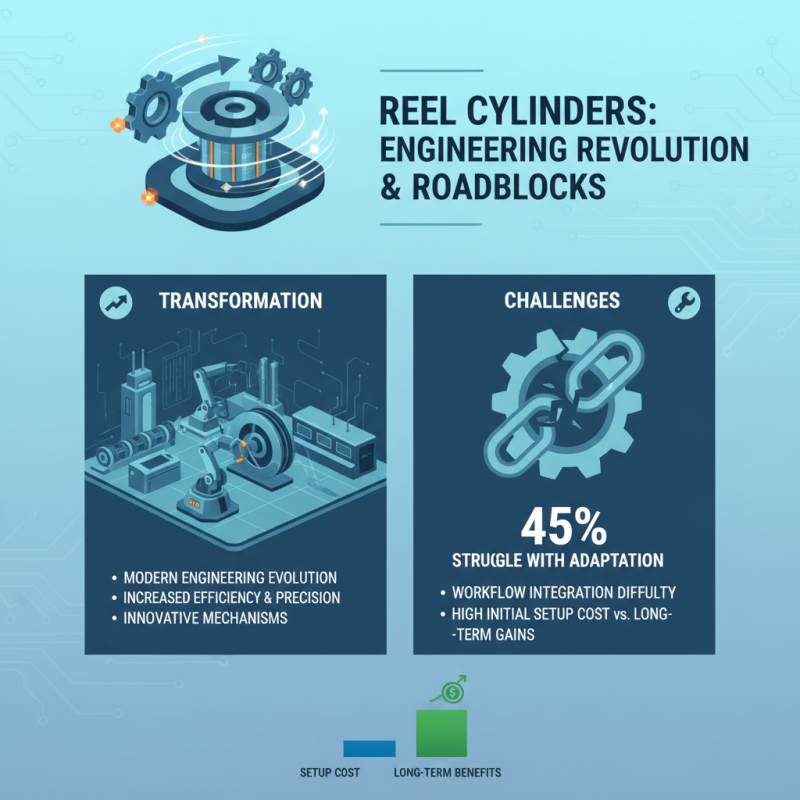

The reel cylinder plays a pivotal role in modern engineering. Its innovative design techniques reflect a push towards efficiency and functionality. Engineers focus on enhancing the durability and versatility of these components. New materials are being tested to improve strength while reducing weight.

Tips: Always consider material compatibility. This can significantly affect performance.

Technological advancements have led to smarter designs. For instance, integration with IoT is becoming common. This allows for real-time monitoring. Engineers can observe data that drives innovation further. However, adapting to new technologies presents challenges.

Tips: Keep testing prototypes. This ensures reliability before full-scale production.

The future will demand even more from reel cylinder designs. Sustainable practices are crucial. Engineers must find eco-friendly materials and processes. Balancing innovation with practicality is essential for success. The journey has ups and downs, but learning from mistakes leads to better designs.

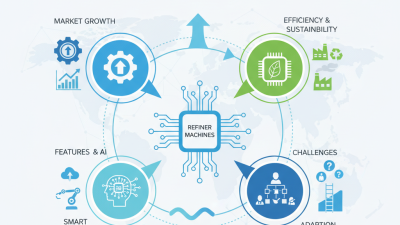

The implementation of reel cylinders is transforming modern engineering. Yet, industries face notable challenges in their integration. Data from recent industry reports indicate that nearly 45% of companies struggle with adapting existing workflows to accommodate these systems. This resistance often stems from the perception that the initial setup expense outweighs potential long-term benefits.

A primary concern is the complexity of installation. Many engineers find it challenging to correctly position and calibrate these cylinders. Misalignment can lead to increased operational costs. The market report shows that companies experience up to a 30% loss in efficiency due to installation errors.

**Tip:** Consider investing in training sessions for your workforce. Properly trained staff can mitigate installation issues and enhance performance.

Another hurdle is maintenance. Reel cylinders require regular upkeep to ensure they function optimally. Companies report that neglecting maintenance can result in breakdowns, leading to costly downtimes. Regular checks can prevent up to 25% of unexpected failures.

**Tip:** Establish a routine maintenance schedule. This proactive approach helps catch potential issues before they escalate.

In light of these challenges, many companies are exploring innovative solutions. Remote monitoring technologies are emerging as a viable answer. By employing IoT connectivity, systems can alert technicians to potential failures, significantly reducing maintenance costs and downtime.