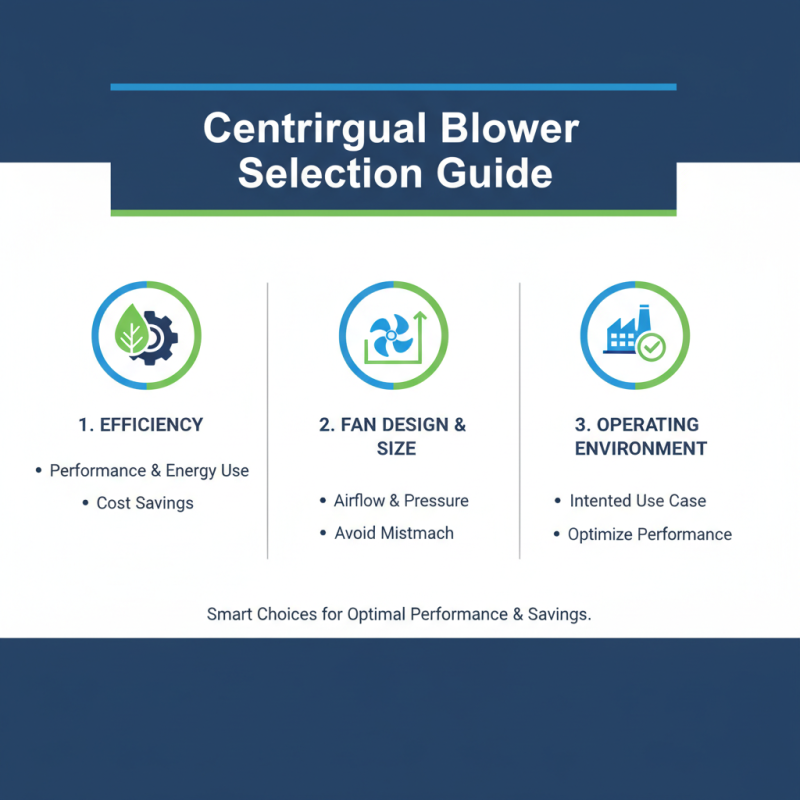

Choosing the right centrifugal blower is crucial for optimizing performance and efficiency. This decision can impact various aspects of your operations, from energy consumption to air quality. Centrifugal blowers are commonly used in diverse applications, including HVAC systems, pharmaceuticals, and industrial settings.

Understanding your specific needs is key to making an informed choice. Factors like airflow rate, pressure, and noise levels affect performance. Many buyers overlook these elements and make impulsive purchases. It’s vital to evaluate your requirements thoroughly before committing.

In addition, consider the blower's maintenance and durability. Selecting a model that requires frequent repairs can lead to unexpected costs. Seek expert advice if you're unsure. Identifying the right centrifugal blower means understanding both your immediate and long-term needs.

Centrifugal blowers are crucial in various industrial applications. They efficiently move air or gas through rotary motion. The design helps maintain consistent airflow while handling different pressures. Industries like manufacturing, HVAC, and wastewater treatment rely heavily on these blowers.

When selecting a centrifugal blower, consider efficiency. A more efficient model may save money on energy bills. However, efficiency ratings can sometimes be misleading. Look for real-world performance data. Also, ensure the blower suits your specific needs. Not all blowers are suitable for high-pressure environments.

Noise levels matter too. Some blowers can be surprisingly loud. You might think all blowers are noisy. But some models operate quietly. Take this into account based on your workspace. Lastly, don’t overlook the maintenance aspect. Regular upkeep is vital for longevity. A cheaper blower might require more frequent repairs, leading to higher costs.

When selecting a centrifugal blower, consider its efficiency. Efficiency impacts performance and energy consumption. A blower that operates well in its intended environment can lead to significant cost savings. Look at the fan design and size. Different designs can affect airflow and pressure. A mismatch may result in suboptimal performance.

Next, review the noise level. Some blowers operate quietly, while others can be quite loud. Excessive noise may not only be irritating but could also indicate inefficiency. Consider where the blower will be used. An industrial setting may tolerate more noise than a cleanroom or office environment.

Don't overlook the maintenance requirements. Some blowers need frequent servicing, while others are low-maintenance. Calculate the long-term costs associated with upkeep. Also, think about installation space. Ensure the chosen blower fits within your space constraints. The dimensional requirements often require careful planning. Small details matter in the overall selection process.

When choosing a centrifugal blower, evaluating performance metrics is crucial.

Airflow is one of the most important factors. It directly impacts how effectively the blower can move air. Look for a blower that offers the right airflow rating for your application. A blower with too low airflow won’t meet your needs. Conversely, an excessively powerful blower can lead to energy wastage.

Pressure is another key metric. It indicates the resistance the blower can overcome. Higher pressure ratings can benefit certain industrial applications. For example, if the system has narrow ducts, more pressure may be necessary. However, be mindful that high-pressure blowers can consume more energy. Balancing pressure and airflow is not always straightforward.

Energy consumption must not be overlooked. A blower may have excellent airflow and pressure ratings, but if it consumes too much energy, it can be costly over time. Look for efficiency ratings and operational costs. Some blowers seem cheaper initially but may lead to high electricity bills. Weighing these metrics carefully will lead to a more informed decision in the long run.

When selecting a centrifugal blower, considering noise levels is crucial. High noise can lead to discomfort in work environments. Ensure that the blower you choose operates within acceptable limits. This can enhance worker satisfaction and productivity. Loud blowers can create disturbances, affecting communication and focus.

Vibration is another key factor. Excessive vibration can cause mechanical wear and tear. It may also lead to misalignment of components over time. Take note of vibration ratings provided by manufacturers. A blower with low vibration levels typically results in a smoother operation. This can extend the lifespan of equipment and reduce maintenance costs.

Analyze the specific needs of your application. Are low noise and minimal vibration a priority? If so, invest time in evaluating different models. Don't overlook the importance of these factors in achieving optimal performance. Balancing them with airflow and efficiency will lead to better outcomes. Make informed decisions to avoid future regrets.

When selecting a centrifugal blower, material and design are key factors. Consider the environment where the blower will operate. Harsh conditions, such as high humidity or corrosive substances, require durable materials. Stainless steel or coated metals often outperform others in these scenarios. Plastic blowers may suffice in less demanding situations, but they risk damage over time.

Design plays an equally critical role in maintenance needs. A blower that is easy to access for service will save time and effort. Look for designs with removable covers and minimal internal components. This can ease the cleaning process and ensure there are fewer places for debris to accumulate. Despite these considerations, complexities in design can lead to problems. Sometimes, a sleek design may be less practical for maintenance.

It's vital to evaluate your specific needs carefully. Quick fixes can sometimes result in long-term issues. For example, prioritizing aesthetics over functionality might result in higher operational costs. Balancing durability with effective design is no small task, but it’s essential for optimal performance. Always reflect on how your choices align with your operational goals.