In the competitive landscape of the paper industry, optimizing "Paper Machine" efficiency is essential. Each paper machine has unique characteristics and demands. Small adjustments can lead to significant improvements in output and quality.

Efficiency goes beyond mere technology. It involves understanding the entire production process. Factors like raw material quality, machine settings, and operator expertise all play crucial roles. Manufacturers must be willing to reflect on current practices and identify bottlenecks.

Investing in employee training can enhance machine performance. Operators should routinely monitor parameters for optimal functioning. However, it’s important to remain open to change. Not every adjustment will yield immediate results. Continuous evaluation is key to maintaining productivity in a dynamic market.

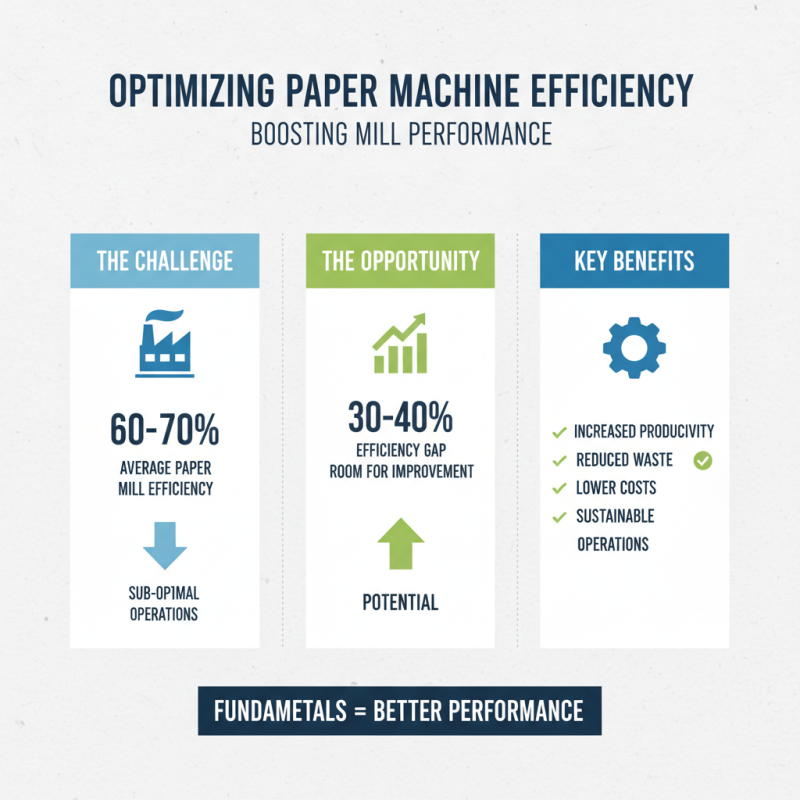

Optimizing paper machine efficiency and productivity is crucial for successful operations in the paper industry. Understanding the fundamentals can significantly impact overall performance. Recent studies show that an average paper mill operates at only 60-70% efficiency. This gap presents a substantial opportunity for improvement.

Many factors can hinder efficiency. For instance, mechanical downtime, which can reach up to 20%. Regular maintenance can minimize such downtime, yet not all mills make it a priority. Training operators is essential, as their skills directly affect machine performance. It is reported that properly trained operators can reduce waste by 15%, highlighting the importance of human factors in productivity.

Furthermore, integrating advanced monitoring technologies can yield benefits. Real-time data helps identify issues quickly, potentially improving efficiency by 10-15%. However, not all facilities invest in these systems. This reluctance can stem from budget constraints or a lack of understanding of their long-term benefits. In striving for higher productivity, mills must confront these challenges and reassess their current strategies.

Optimizing the efficiency of paper machines involves several key factors.

One major aspect is the quality of raw materials. Inconsistent pulp quality can lead to various production issues. This inconsistency affects sheet formation and overall strength. Monitoring the raw material blend is crucial. Adjusting these materials can enhance the final product.

Another significant factor is the machine settings. Each paper machine operates optimally under specific conditions. Pressures, temperatures, and speeds must be fine-tuned regularly. Operators often overlook minor adjustments, which can lead to inefficiencies. Regular training and feedback can help negate this issue. Machine maintenance also plays a vital role. Wear and tear can hinder performance. Operators need a routine check on all components.

Lastly, energy consumption in paper production must be considered. Comparing different processes can reveal areas for improvement. Sometimes, the focus on maximizing speed results in higher energy costs. Thus, a balance needs to be struck to avoid waste. Analyzing energy data can uncover hidden inefficiencies. Reflecting on these key aspects can pave the way for increased productivity in paper manufacturing.

Monitoring and analyzing paper machine operations is essential for improving efficiency. Regularly checking key performance indicators can reveal significant insights. Operators must focus on metrics like speed, quality, and downtime. Using real-time data can help detect issues early. Observations often show fluctuations in machine performance during production runs. This inconsistency can hinder overall output.

One useful technique is implementing vibration analysis. This method identifies mechanical issues before they lead to failure. Another technique involves using moisture sensors. Tracking moisture levels in real-time ensures optimal drying processes. Operators should not overlook the importance of employee feedback. Workers on the ground often provide insights into potential inefficiencies.

However, relying on data alone can be misleading. Data can misrepresent the situation if not interpreted correctly. There are occasions when human error affects measurements. A critical approach is to combine data analysis with on-ground observations. This blend offers a fuller picture of operations. Regular training sessions can enhance the team’s ability to interpret data effectively. Engaging employees in the optimization process fosters a culture of continuous improvement.

This chart illustrates key performance metrics for optimizing paper machine efficiency in 2026, including speed, pulp quality, energy consumption, downtime, and waste percentages.

In paper production, maintenance plays a crucial role in optimizing machine efficiency. Regular checks can prevent unexpected breakdowns. Scheduled maintenance ensures that machinery operates smoothly. Delaying these tasks might save time initially but could lead to costly repairs later. Operators must recognize signs of wear and address them promptly.

Upgrading equipment is another key aspect. New technologies can enhance productivity. However, not all upgrades are necessary or effective. Some improvements may not yield tangible benefits. It's essential to analyze the current processes before making decisions. Evaluating past performance can provide insights into what changes would be beneficial.

Employee training is vital as well. Workers must understand the new systems and machinery. Knowledge gaps can hinder performance. Investing in training does require time and resources, but the return on investment can be significant. Engage staff in continuous improvement discussions. Their feedback can highlight potential issues and spark innovative solutions.

Innovative technologies are transforming paper machine efficiency significantly. Recent studies show that adopting digital monitoring systems can enhance productivity by up to 15%. These systems allow real-time tracking of machine performance. Operators can address issues quickly, minimizing downtime.

Moreover, automation in paper production is gaining traction. The use of AI-driven predictive maintenance reduces unexpected failures. According to industry reports, companies implementing such systems observed a 20% increase in operational reliability. However, some facilities still struggle with initial integration costs.

Another promising area is the use of advanced materials in paper machines. These materials can improve durability and reduce maintenance needs. Though costs may be higher upfront, they lead to long-term savings. It’s a trade-off many mills are still evaluating. The path to optimized efficiency is not flawless; some methods require careful reconsideration for full benefits.