When selecting cutting equipment for your projects, the choices can be overwhelming. Renowned industry expert John Steel once stated, "Quality cutting equipment is crucial for precision and efficiency." His insights highlight the importance of making informed decisions.

Cutting equipment comes in various forms, including saws, knives, and lasers. Each type serves specific needs, from heavy-duty industrial tasks to delicate craft work. The wrong tool can lead to poor results and wasted materials. It's essential to analyze your requirements carefully and choose equipment that meets them.

Consider factors such as the material you will cut, the frequency of use, and the level of precision required. It's easy to overlook these details in the excitement of a new project. However, taking the time to evaluate your options can save you frustration later. Aim for equipment that not only provides power but also enhances control and safety.

When it comes to cutting equipment, understanding the various types is crucial. Different industries use specific tools for distinct applications. For example, a report by the Robotics Industry Association notes that nearly 50% of manufacturers employ laser cutting for precision tasks. These machines cut through metals and plastics with extreme accuracy. However, they require regular maintenance to ensure optimal performance. This is often overlooked, leading to downtime.

In the woodworking sector, saws remain a primary choice for cutting lumber. A survey by Woodworking Network highlights that 65% of carpenters favor table saws for their versatility. However, using the wrong blade can result in poor cuts and safety issues. Users must assess their needs before making a purchase, considering factors like material type and thickness. This underlines the importance of matching cutting equipment to specific tasks, as misalignment can lead to inefficient work and increased costs.

Operators also need to consider user ergonomics. Equipment that feels heavy or awkward can lead to fatigue and mistakes. A study from the National Institute for Occupational Safety and Health found that improper equipment leads to workplace injuries in 30% of cases. It's essential to test the feel and usability of cutting equipment before committing. A few minutes of research can save substantial time and effort in the long run.

When selecting cutting equipment, blade material plays a crucial role in determining efficiency. Various materials offer different performance levels. High-carbon steel blades are known for their sharpness. However, they may require frequent sharpening. On the other hand, stainless steel boasts durability but can lack the same edge retention.

Consider the application before choosing a blade material. For everyday use, an alloy of high-carbon and stainless steel might suffice. Yet, in heavy-duty tasks, specialized materials like ceramic may be favorable for their hardness and wear resistance. This choice can impact both cost and effectiveness.

It's wise to reflect on your needs. A more expensive option doesn't always guarantee better performance. Sometimes, a simple blade serves the purpose just as well. Think about the types of materials you often cut and the required precision. Efficiency stems from understanding your own cutting habits and adapting your tools accordingly.

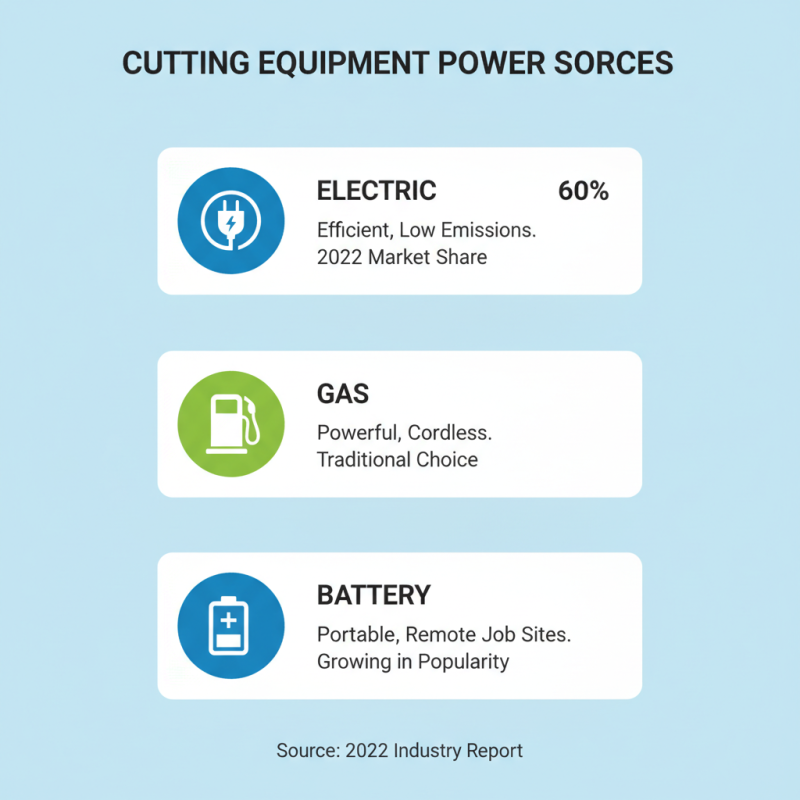

When selecting cutting equipment, understanding the power source's role is crucial. Most cutting tools rely on electric, gas, or battery power. A 2022 industry report indicated that electric-powered tools accounted for 60% of the market due to their efficiency and low emissions. However, battery-powered equipment is gaining traction for its portability, especially in remote job sites.

It's important to consider the specific tasks at hand. For heavier materials, tools with robust power sources are necessary. A tool with a lower power rating may struggle and lead to inefficiencies. Factors such as voltage ratings and amperage can greatly impact performance. Recently, reports showed that equipment exceeding 15 amps performs better in demanding environments, reducing downtime.

However, not all power sources are perfect. Electric tools may limit movement, whereas gas-powered options create exhaust. The user must evaluate their environment and safety requirements. In some cases, a hybrid approach can be beneficial, combining the strengths of different power sources. Evaluation of usage scenarios and tool specifications is key for optimal performance.

Cutting speed plays a critical role in selecting the right cutting equipment. Different materials respond uniquely to cutting speeds. For hard metals, slower speeds are often needed. Faster speeds work better with softer materials, like plastics. Understanding this relationship can save time and enhance quality.

When choosing cutting equipment, consider the thickness of the material. Thicker materials require lower speeds to prevent damage. In contrast, thin materials can handle faster cuts. Experimenting with different speeds may lead to unexpected results. This trial-and-error process can help refine your choices.

Here are some tips to keep in mind: Always prioritize the material type when selecting equipment. Evaluate its thickness correctly. Assess your cutting volume to ensure efficiency. Lastly, never overlook safety features when making a decision. These aspects could make a significant difference in your cutting process.

When selecting cutting equipment, safety features should be a top priority. Look for tools with protective guards and non-slip handles. These features prevent accidents and provide comfort during use. A good grip is essential. If the tool feels unstable, it can lead to mistakes. Choosing heavy-duty materials can also enhance safety; they withstand wear and reduce the chance of breakage.

Ergonomics play a crucial role in user comfort. Tools should fit comfortably in your hand. Pay attention to the weight and balance of each piece. Heavy tools can lead to fatigue quickly. Adjustable designs offer versatility and ease. They allow you to change angles, making tasks more efficient. Still, some users neglect testing different options. This can lead to discomfort or injuries over time. Quality cutting equipment not only saves time but also protects your well-being. Explore various designs to find what truly suits you.