In the manufacturing world, the Grinder Machine plays a crucial role. It enhances precision and efficiency across various industries. According to a report from Grand View Research, the global grinding machine market was valued at over $4 billion in 2020. This figure is expected to grow as technology advances.

Different types of grinder machines are available, each suited for specific applications. From surface grinders to cylindrical grinders, each type has unique features. However, the availability of so many options can lead to confusion. Many manufacturers may not choose the best equipment for their needs, potentially impacting productivity and quality.

Understanding these machines is vital. It can help businesses make informed decisions. With the right grinder machine, companies can optimize their processes. Yet, selecting the wrong type can lead to inefficiencies. This highlights the importance of knowing the ten essential grinder machine types. They are not just tools but pivotal in driving innovation and ensuring quality in production.

When exploring grinder machines, understanding their types and key features is essential. There are various categories like blade, burr, and surface grinders. Each type serves specific purposes in industries like manufacturing and food production. According to a recent market report, the global grinding machines market is projected to reach $5.2 billion by 2025, indicating rising demand.

Blade grinders are popular for their simplicity and affordability. They employ sharp blades to chop down materials. However, their inconsistency in particle size can be a drawback. On the other hand, burr grinders provide uniform grind size. They crush beans or materials between two surfaces, yielding better quality. Yet, they tend to be pricier and may require more maintenance.

Surface grinders play a crucial role in achieving precision in machining applications. They use a spinning wheel to create flat surfaces. This type is vital in metalworking. However, improper use can lead to errors in the final product, highlighting the importance of operator training. Understanding these nuances can significantly enhance the efficiency and quality of production processes.

When comparing bench grinders and angle grinders, several factors come into play. Bench grinders are stationary tools, anchored on a work surface. They excel in sharpening blades and shaping metal pieces. Often, they come with two grinding wheels, allowing for versatility. Their design provides better stability during use, making them ideal for detailed tasks.

On the other hand, angle grinders are handheld devices known for their portability. They are incredibly versatile, cutting through various materials and grinding surfaces. With the right attachment, they can polish or even sand. The downside? Their lightweight design can lead to less control, especially for intricate projects. Users may find themselves needing to practice more to achieve precise results.

While both tools serve valuable purposes, the choice depends on specific needs. Bench grinders may encourage longer and more careful work sessions. In contrast, angle grinders are perfect for quick jobs that require mobility. Each tool has its strengths and weaknesses, and understanding these can lead to more effective project outcomes.

| Grinder Type | Description | Best For | Power Source | Typical Uses |

|---|---|---|---|---|

| Bench Grinder | A stationary type of grinder used for sharpening edges and finishing surfaces. | Sharpening tools and blades. | Electric | Tool sharpening, polishing, and deburring. |

| Angle Grinder | A versatile hand-held tool for grinding, cutting, and polishing. | Metalworking and masonry. | Electric or battery-powered | Cutting metals, tiles, and grinding surfaces. |

| Die Grinder | A handheld tool used for precision grinding. | Detail work and engraving. | Electric or pneumatic | Engraving and polishing small details. |

| Belt Grinder | Uses an abrasive belt for grinding or finishing work. | Metal fabrication. | Electric | Sharpening, shaping, and polishing metal. |

| Angle Polisher | Used specifically for polishing surfaces. | Automotive and woodworking. | Electric | Polishing cars and furniture. |

| Surface Grinder | A machine tool that uses a rotating abrasive wheel. | Large surface grinding applications. | Electric | Finishing flat surfaces and precision machining. |

| Floor Grinder | Designed for grinding concrete floors. | Industrial floor maintenance. | Electric or gasoline | Preparing surfaces and polishing concrete. |

| Wet Grinder | Uses water to keep the temperature down while grinding. | Sharpening tools with minimal heat. | Electric | Sharpening chisels and blades. |

| Multi-Tool Grinder | Combines various grinding mechanisms in one tool. | Versatile applications. | Electric | Multiple tasks, such as sharpening, polishing, and cutting. |

| Cylindrical Grinder | Used for grinding the external and internal cylindrical surfaces. | Precision machining. | Electric | Finishing shafts and rods. |

Die grinders are versatile tools in various industries. They excel in tasks such as shaping, smoothing, and polishing materials. Many professionals rely on them for precision work. The tools can handle metal, plastic, and wood with ease.

However, while die grinders can increase efficiency, there are limitations. They can generate excessive heat during prolonged use. This can affect both the material and the tool's lifespan. Additionally, inexperienced users might struggle with controlling the tool's speed. This can lead to mistakes, affecting the quality of the work.

Understanding how to use die grinders effectively is crucial. Various applications require different techniques. For example, grinding a metal surface demands a steady hand. Conversely, polishing soft materials might need a gentler touch. Mistakes in these areas can waste time and resources. Being aware of these factors helps users improve their skills. Remember, practice makes perfect, but mindfulness is key.

Tool and cutter grinders are essential machines in the manufacturing sector. They play a crucial role in producing precise cutting tools. According to industry reports, nearly 70% of companies rely on these grinders for tool maintenance and repair. This ensures that tools remain sharp and effective throughout their lifecycle. The versatility of these machines allows them to handle various materials, including metals and plastics, making them indispensable in many workshops.

Understanding their features is vital. Tool and cutter grinders can sharpen a range of tools, from end mills to step drills. This adaptability can improve productivity. However, some users report challenges, such as the learning curve associated with mastering these machines. Even experienced operators sometimes struggle with achieving the desired precision. Regular training could mitigate these issues.

Moreover, quality control is essential when using this machinery. Reports indicate that 30% of tool failures stem from improper grinding techniques. Therefore, investing in training and best practices is crucial. Ignoring this aspect can lead to expensive downtime and production delays. In conclusion, while tool and cutter grinders offer flexibility, users must remain diligent to maximize their effectiveness.

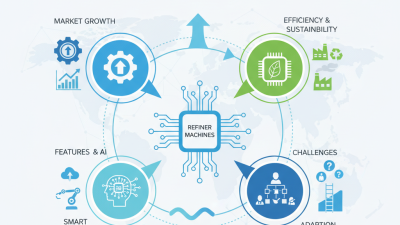

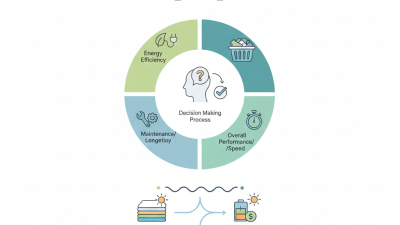

When selecting a grinder machine, several key considerations emerge. The type of material you will be grinding is crucial. Different materials require varying levels of power and consistency. For example, grinding hard materials like metals demands a robust machine with a powerful motor. A recent industry report revealed that over 75% of manufacturers prefer machines with adjustable speeds for diverse applications. This flexibility can lead to better results in productivity.

Another factor to consider is the machine size and features. Smaller machines may be more affordable but may lack the efficiency of larger models. In a survey conducted among industry experts, nearly 60% stated that larger, more specialized grinders lead to higher quality outputs. It's essential to analyze your workspace as well. A compact machine may save space, but could limit performance for extensive jobs.

The maintenance aspect is often overlooked. Regular upkeep is necessary to ensure longevity. Machines that require frequent repairs can become costlier over time. The same report highlighted that companies neglecting maintenance face a 30% increase in operational costs. Thus, understanding these key aspects can refine your decision-making process and enhance your investment's value.