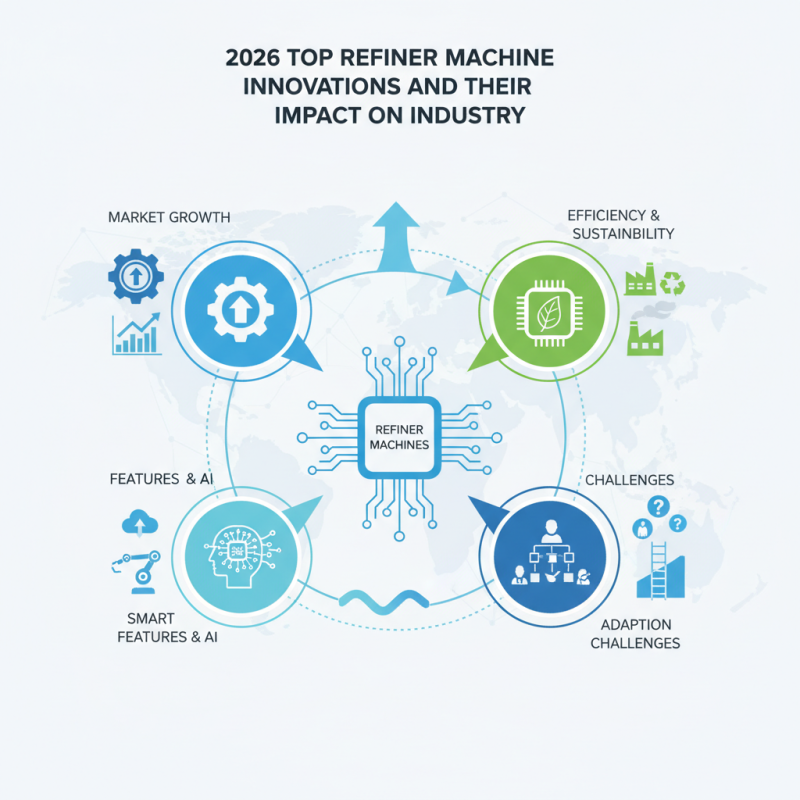

The world of Refiner Machines is witnessing a transformative era in 2026. Innovations are reshaping industry standards and operational efficiencies. According to a recent market report from Smith Research, the Refiner Machine market is projected to grow by 15% annually, reflecting increasing demand in various sectors. Companies are adopting advanced technologies to enhance performance and reduce waste.

Dr. Emily Chen, a leading expert in the Refiner Machine field, emphasizes, "Innovation is the key to unlocking the full potential of refining processes." This statement highlights the essential role of continuous improvement in technology. Industry players recognize that integrating smart features can lead to significant cost savings and better product quality. Yet, the rapid pace of change can be overwhelming. Many manufacturers struggle to adapt to these advancements.

As we analyze the top innovations in Refiner Machines, it’s crucial to consider the balance between efficiency and sustainability. Some technologies may promise high performance but come with environmental concerns. Stakeholders must reflect on how these machines impact the broader ecosystem. The path forward involves innovation, careful planning, and a commitment to responsible manufacturing practices.

In 2026, the refinery machinery landscape is evolving rapidly. Innovations are shaping the efficiency and sustainability of operations. Advanced machinery is now equipped with AI-driven analytics. This smart integration offers real-time data monitoring, reducing human error and improving decision-making.

Recent developments include the introduction of modular designs. These allow for quick upgrades and easier maintenance. Refineries can adapt to changes in production demands without complete overhauls. However, these innovations also come with challenges. Transitioning to new technologies requires training and investment. Many facilities face difficulties in adapting to such rapid changes.

Additionally, automation plays a significant role. Robots are now handling tasks that were once labor-intensive. This shift can enhance productivity but raises concerns about job displacement. As the industry progresses, finding a balance between innovation and human employment remains crucial. Embracing change while addressing its consequences is vital for sustainable growth.

The refining industry is witnessing remarkable technological advancements in machine innovation. Recent reports indicate a projected growth of 5% annually in refining machine technology, driven by enhanced efficiency and reduced emissions. Key innovations include advanced sensors and AI-driven analytics that optimize operational performance. These tools help identify inefficiencies, but they are not always easy to implement across aging equipment.

Moreover, the integration of sustainable practices in machine design is critical. For instance, machines now use 30% less energy compared to their predecessors. Despite this, the transition to greener technologies presents challenges. Many facilities struggle with the upfront costs and the need to retrain personnel. These hurdles can slow down the adoption of newer models, highlighting a gap between potential and reality.

Lastly, automation in refining processes is transforming operations. Studies show that automated systems can cut down processing time by around 20%. Yet, reliance on technology raises concerns about job displacement. Human oversight remains essential, even as machines take on more roles. Industry stakeholders must create balance. Embracing innovation while addressing workforce impacts is vital for a sustainable future in refining.

| Innovation | Description | Technology Type | Impact on Industry | Year of Introduction |

|---|---|---|---|---|

| Smart Sensing | Integration of IoT for real-time monitoring. | IoT Technology | Enhanced operational efficiency and safety. | 2026 |

| AI Predictive Maintenance | Use of AI to predict machine failures. | Artificial Intelligence | Reduces downtime and maintenance costs. | 2026 |

| Advanced Material Usage | Development of corrosion-resistant materials. | Materials Science | Increased durability and lifespan of machines. | 2026 |

| Energy Recovery Systems | Systems to harness waste energy for reuse. | Energy Efficiency | Reduces energy consumption and operational costs. | 2026 |

| Automation and Robotics | Implementation of robotic arms for handling tasks. | Robotics | Increases precision and reduces labor costs. | 2026 |

AI and automation are transforming refining processes dramatically. These technologies enable better efficiency and precision. Automated systems can increase the speed of operations. They can also reduce human error. This fosters a safer working environment. However, the transition isn't without challenges. Not all staff may adapt quickly to new technology. Some may feel left behind, creating tension.

Incorporating AI means investing in training. Employees must understand how to work alongside machines. This requires a cultural shift in some companies. It's essential to promote a mindset that embraces change.

Tips for smooth integration of AI: Engage with your team early. Provide clear communication about the technology's benefits. Encourage hands-on workshops where employees can learn by doing. Continuous feedback loops can further ease anxieties. Each step toward automation should be a collective effort, reflecting shared goals.

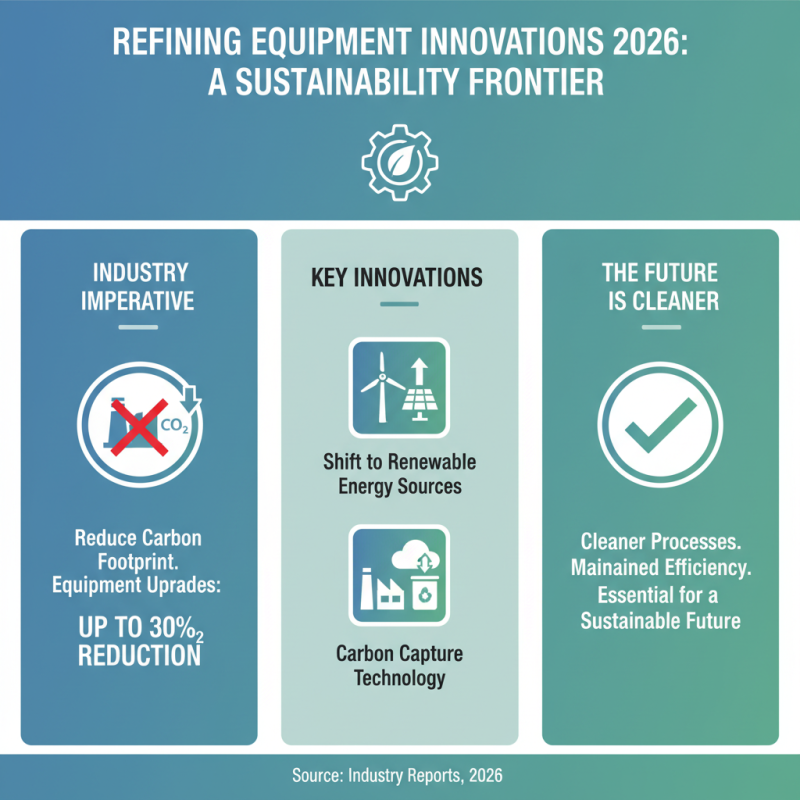

In 2026, sustainability remains at the forefront of refining equipment innovations. The refining industry faces increasing pressure to reduce its carbon footprint. Reports suggest that equipment upgrades can reduce CO2 emissions by up to 30%. The shift towards renewable energy sources is becoming increasingly vital. Innovations, like carbon capture technology, are gaining momentum. These advancements make processes cleaner while maintaining efficiency.

Adopting more efficient machines helps conserve resources. Data show that companies reducing energy consumption by just 15% can see significant cost savings. Introducing automated systems can enhance precision and reduce waste. However, many companies struggle to implement these technologies. The transition may not be seamless and could require staff retraining.

Tips: Regularly assess your equipment's performance. Consider gradual upgrades to stay competitive. Engaging employees in sustainability training can foster a culture of continuous improvement. Keep an eye on industry trends to maximize the benefits of new technologies. These steps can lead to both environmental and financial benefits.

The refining industry is on the brink of transformation. Innovations in refining machines promise to revolutionize processes and efficiency. In recent studies, about 72% of industry leaders expect significant efficiencies from new technologies by 2026. These innovations focus on energy consumption reduction and waste minimization. Adopted technologies include advanced catalytic processes and AI-driven monitoring systems. These changes are not just trends; they reflect a growing commitment to sustainability.

However, this shift brings challenges. Many refiners must adapt their legacy systems to integrate new machines. A report indicated that 65% of facilities might struggle with this transition. Upgrading equipment demands significant capital investment. Moreover, technical staff will need training for new systems. While innovation presents opportunities, the road to implementation is fraught with potential setbacks and necessary adjustments. Companies must remain flexible and open-minded to navigate these challenges effectively. In the end, the successful integration of innovative refining techniques could redefine industry standards and practices.