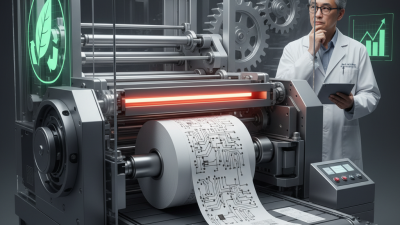

Choosing the right Kraft Paper Machine is crucial for businesses aiming for efficiency. Expert Emma Greene, a consultant in the pulp and paper industry, states, "A well-selected machine can elevate your production quality." This highlights the importance of making informed choices in this sector.

Investing in a Kraft Paper Machine involves various considerations. Different machines offer unique features and capabilities. Some are designed for speed, while others focus on quality. Understand the requirements of your production line before making a decision. Researching effectively can save time and resources.

Not all machines will suit your needs perfectly. Some may not deliver promised results. It’s essential to seek feedback from other users. Inadequate research may lead to regret later. Balancing costs with quality is often a challenging task. Be mindful and trust your instincts during the selection process.

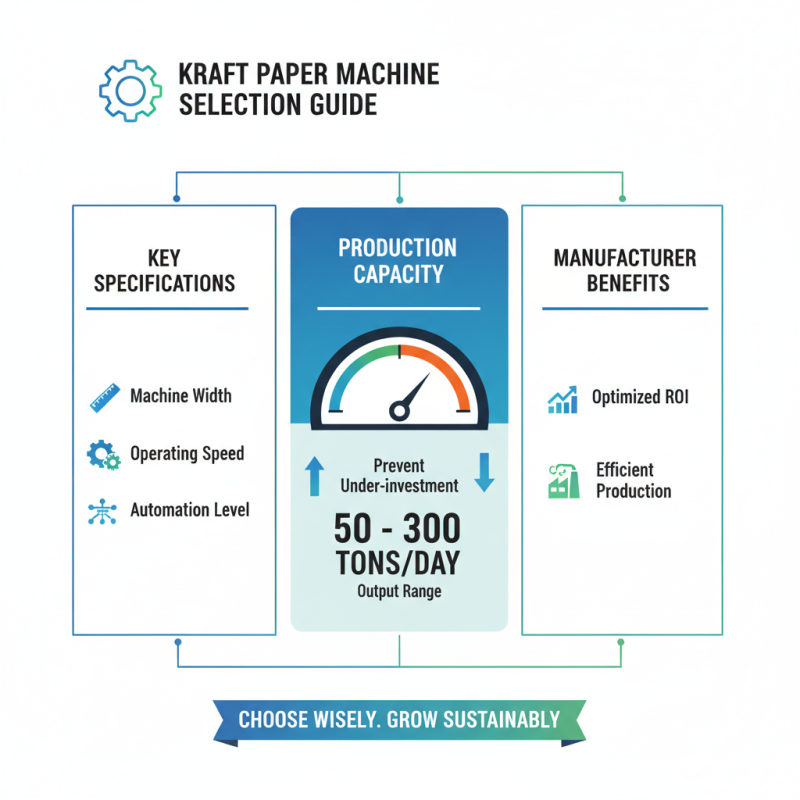

Choosing the right kraft paper machine is crucial for manufacturers. Specifications play a significant role in this decision. For instance, the production capacity is one key factor. Many machines offer a range of output levels from 50 to 300 tons per day. Understanding these capacities can prevent over or under-investment.

Another important specification is the energy consumption. Some machines can consume up to 20% less energy than others, significantly impacting operational costs. A report by the International Energy Agency highlighted that improving energy efficiency can save companies substantial amounts annually. It’s essential to assess not only the specifications but also the sustainability of the machinery.

Quality control is often overlooked in terms of specifications. The precision of the paper produced affects customer satisfaction directly. Machines should meet strict quality standards. Data shows that inconsistencies in paper quality can lead to a 15% increase in waste rates. Choosing a machine that says ‘quality’ can be challenging but is vital. Overall, focusing on specifications helps align business needs with technological advancements.

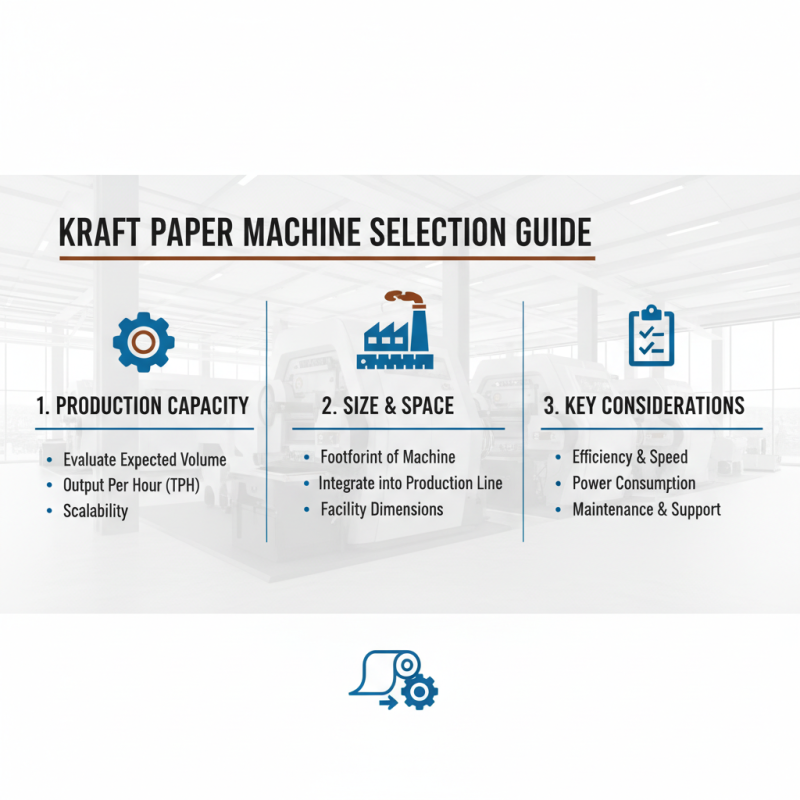

When selecting a Kraft paper machine, evaluating production capacity is critical. Look for machines that can handle your expected volume. A machine’s output per hour matters greatly. Consider the size of your production line and the space available. Ensure that the machine can fit in your facility without interruptions.

Efficiency metrics are another key factor. They indicate how well the machine converts raw material into finished products. Check the energy consumption of the machine. High efficiency can lead to significant cost savings. However, some machines may seem efficient on paper but struggle in practice. Observe user reviews and real-world performance. It's essential to analyze the reported metrics versus your specific needs.

Production speed should not compromise product quality. Balancing these two aspects is often tricky. Machines with high speed may produce defects if not properly adjusted. Regular maintenance is necessary to keep the machine running efficiently. Therefore, consider long-term reliability and maintenance costs while making your decision.

Assessing the quality of raw materials is critical for any kraft paper machine.

High-quality wood fibers yield better results. Studies show that fibers with a length greater than 1.5 mm enhance tensile strength.

Conversely, poor-quality fibers result in weak paper. Choosing materials with optimal moisture content is essential; ideally, it should be between 9% and 12%.

The pulping process also significantly affects kraft paper quality. A recent industry report indicated that the pulping efficiency can vary widely; efficient methods can achieve up to 95% yield. Inefficient processes can lead to considerable fiber loss.

Diversifying pulping methods may enhance fiber recovery and overall quality. However, some methods might be more complex and costly, requiring in-depth examination.

It's important to reflect on these factors during the selection process. Quality assurance in raw materials and the pulping process directly impacts production costs.

A company should strive for a balance between cost-efficiency and material quality. New technologies are evolving, yet traditional methods remain important.

Finding the right fit for a specific production line can make all the difference.

When selecting a kraft paper machine, energy consumption and cost-effectiveness are critical factors. Efficient machines can significantly reduce operational costs. Assessing energy consumption per production unit helps in making an informed decision. Look for machines designed with energy-saving features. These could lead to substantial savings over time.

As you explore options, consider the machine's production capacity. Higher output may seem appealing, but it should align with your energy costs. Evaluate the return on investment. Sometimes, cheaper machines may end up costing more due to high energy requirements. Balance is essential.

Keep maintenance in mind as well. Frequent repairs can escalate costs, affecting overall efficiency. Investigate the availability of parts. A machine might have a low initial price, yet high long-term expenses if parts are hard to find. Carefully weigh your options to find a machine that matches your production needs while being cost-effective and energy-efficient.

| Tip No. | Criteria | Considerations | Energy Consumption (kWh/ton) | Cost-Effectiveness Ratio |

|---|---|---|---|---|

| 1 | Machine Efficiency | Production speed, waste reduction | 500 | 1.2 |

| 2 | Material Flexibility | Different pulp types, grades | 450 | 1.5 |

| 3 | Energy Efficiency | Downstream energy use | 350 | 1.8 |

| 4 | Automation Level | Degree of automation and control | 400 | 1.6 |

| 5 | Maintenance Costs | Spare parts availability | 300 | 2.0 |

| 6 | Support & Service | Availability of local support | 460 | 1.4 |

| 7 | Environmental Compliance | Regulatory requirements | 380 | 1.7 |

| 8 | Upgradation Ease | Future-proofing the investment | 520 | 1.1 |

| 9 | User-Friendly Interface | Ease of operation | 370 | 1.9 |

| 10 | Overall Cost of Ownership | Consider total expenses | 550 | 1.0 |

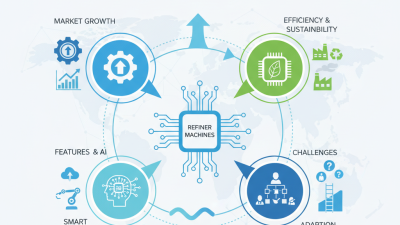

When evaluating kraft paper machines, technological advancements play a key role. Automation features significantly enhance operational efficiency. A recent report by Smith & Associates showed that automated systems can improve production rates by 30%. This can reduce labor costs significantly and minimize human error.

The integration of IoT (Internet of Things) in manufacturing is noteworthy. It allows real-time monitoring and data collection. A statistic from the Paper Industry Technical Association indicates that companies using IoT technologies see a 20% decrease in downtime. However, the initial investment in such technology may be daunting for smaller operations.

Moreover, machine adaptability becomes crucial. A flexible kraft paper machine can accommodate various paper weights and sizes. According to a study by the Global Paper Report, machines that adapt to multiple specifications increase overall market competitiveness. This complexity, however, requires ongoing training and skill development for the workforce. Balancing technological investment with workforce readiness is vital for sustained success.