In the fast-evolving world of manufacturing, the Reeling Machine stands at the forefront of innovation. The year 2026 promises to unveil exciting features that enhance efficiency and productivity. Manufacturers are focusing on intelligent automation and user-friendly interfaces. These advancements will streamline operations and reduce error margins.

Energy efficiency has become a key topic for Reeling Machines. Innovations aim to minimize power consumption while maximizing output. Another area of growth is the integration of IoT technology. This enables real-time monitoring and data analysis, making processes more transparent.

Yet, with these advancements come challenges. As machines become smarter, operators must adapt to new technologies. Training programs will need to evolve alongside. This constant adaptation can be daunting. But it opens doors for new skill sets and expert roles in the industry. Embracing these changes will be crucial for businesses aiming to thrive in this competitive market.

The 2026 reeling machines are set to revolutionize the efficiency of various industries, showcasing key features that enhance productivity. According to a recent industry report, these machines are expected to improve operational speed by 25%. This advancement is crucial in sectors like telecommunications and manufacturing, where time is of the essence.

A significant innovation is the integration of AI-powered controls. These controls optimize the reeling process in real-time, adjusting parameters based on material type and environmental conditions. User feedback indicates that this feature reduces waste by up to 15%. However, reliance on AI does raise questions about machine adaptability in unexpected situations.

Moreover, the ergonomic design enhances user comfort, with 40% of operators reporting reduced fatigue. Adjustable heights allow customization for individual user needs, promoting better safety practices. Yet, manufacturers must carefully balance ergonomic features with machine stability. As innovation progresses, the industry must address these challenges for optimal performance.

The world of reeling machines is evolving rapidly. Innovative technologies are shaping their future. Smart sensors are becoming commonplace. These sensors enhance monitoring and control. They provide real-time data on tension and speed. This data helps operators make informed decisions.

IoT integration is another significant trend. Machines can now communicate with each other. This leads to more efficient operations. Data analytics plays a vital role, too. By analyzing patterns, manufacturers can predict failures. This predictive maintenance can reduce downtime significantly.

However, challenges still exist. High costs of implementation can deter smaller companies. There’s also a learning curve with new technologies. Training is essential to fully utilize these innovations. As the industry adapts, feedback will be crucial. Continuous improvement is necessary to overcome these hurdles. The journey of innovation is ongoing.

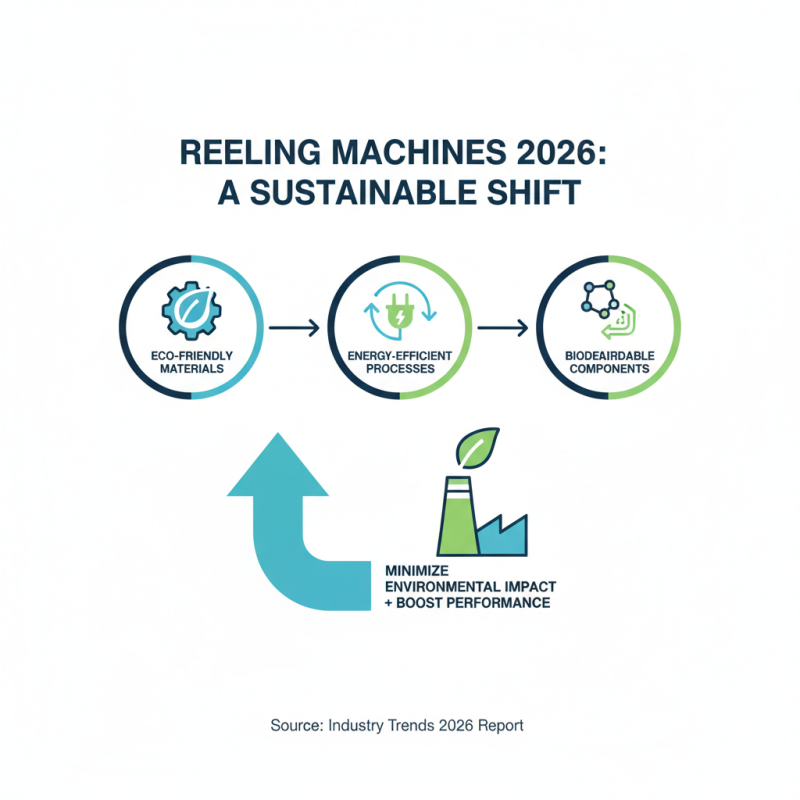

In 2026, sustainability will shape the design and production of reeling machines. Manufacturers will prioritize eco-friendly materials. Innovations may include biodegradable components and energy-efficient processes. This shift aims to minimize environmental impact while boosting performance.

New trends could see a rise in modular designs. Modular machines allow for easy upgrades and repairs. This can lead to less waste. Choosing components wisely can also reduce energy consumption. Flexible production methods might become standard, enhancing efficiency without harming the planet.

Tip: Consider lifecycle assessments when choosing a reeling machine. Analyzing the entire lifecycle helps identify opportunities for sustainability.

Another trend is the integration of smart technology. Many machines will be equipped with sensors. These sensors can monitor energy use in real-time. Users might make better decisions with this data. However, not all companies are ready for this change. Some may struggle to adapt.

Tip: Stay informed about technological advancements. Knowledge can guide smarter, sustainable choices. Embrace new ideas, but reflect on the process. Each step toward sustainability can lead to meaningful improvements.

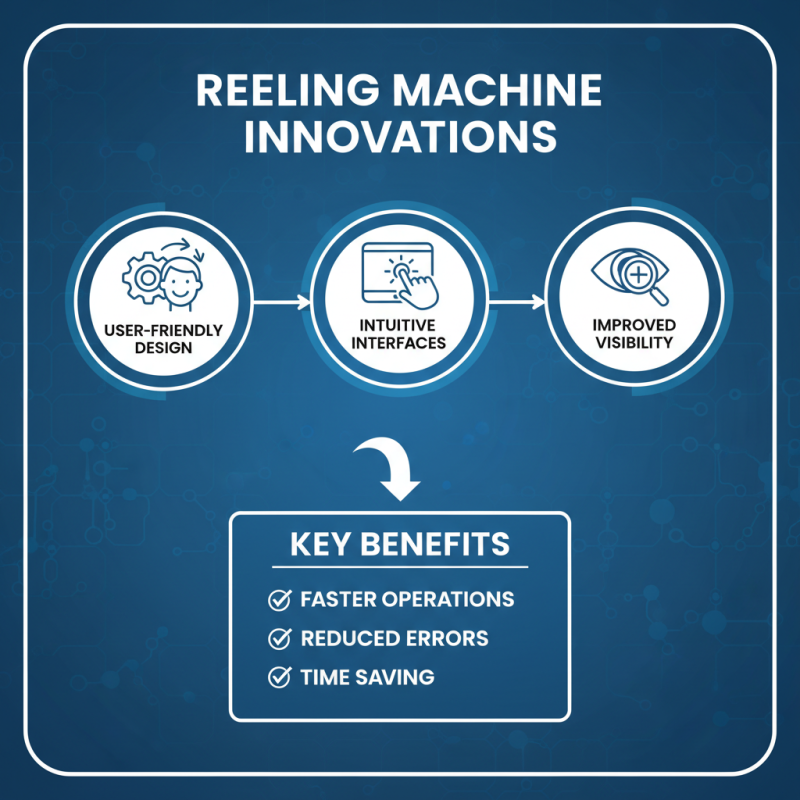

The latest innovations in reeling machine design emphasize user-friendly features. These enhancements aim to make operations simpler. Machines now have intuitive interfaces. Operators can quickly adjust settings. This saves time and reduces errors. Visibility is improved with better display screens.

One standout feature is ergonomic controls. These allow for easier handling during operation. Touchscreens replace complex buttons. Operators can navigate swiftly. It’s essential to reduce fatigue during long shifts. A thoughtful design can greatly enhance productivity.

Tips: Always assess your workspace. A well-organized area can complement the new features. Consider training staff on the latest functions. Familiarity breeds confidence. Reflect on the learning curve. Taking time to adapt is crucial. Embracing these changes can lead to smoother operations. Remember, not every upgrade will suit every user. Evaluate your team’s needs carefully.

The upcoming reeling machines in 2026 promise to integrate smart technology in fascinating ways. Imagine machines that communicate with operators in real-time. This feature will enhance efficiency and reduce errors. Real-time data analysis helps in adjusting operations promptly. For instance, if a fault occurs, the machine can instantly alert the user about potential fixes.

Here’s a tip: Regularly check software updates for your machines. Manufacturers will release improvements. Machine performance can greatly improve with the latest software. Moreover, having access to detailed analytics can help operators understand their production patterns.

Another intriguing advancement is the use of artificial intelligence. Smart machines will learn from past operations. This learning will allow for predictive maintenance. Operators can avoid unexpected breakdowns. You can save on repair costs and reduce downtime.

Always remember to review your machine's capabilities. Understand how much automation you need. A balance between manual control and machine intelligence is crucial. Too much reliance on automation can lead to oversight. Adjusting your methods will help you stay ahead in production efficiency.