A roller tensioner plays a crucial role in maintaining your vehicle's performance. It ensures the proper tension of the timing belt or chain, which is vital for smooth engine operation. If this component fails, several issues can arise. The engine may misfire, leading to reduced power and efficiency.

Maintaining a roller tensioner can save you from costly repairs down the line. Unfortunately, many drivers overlook this essential part. Regular checks can prevent unexpected breakdowns on the road. Having a reliable tensioner helps keep your engine running smoothly and extends its lifespan.

Ignoring the health of your roller tensioner may lead to serious consequences. It can lead to belt slippage or even engine failure. Paying attention to this seemingly small component is paramount for vehicle maintenance. Make it a point to include the roller tensioner in your regular maintenance checklist.

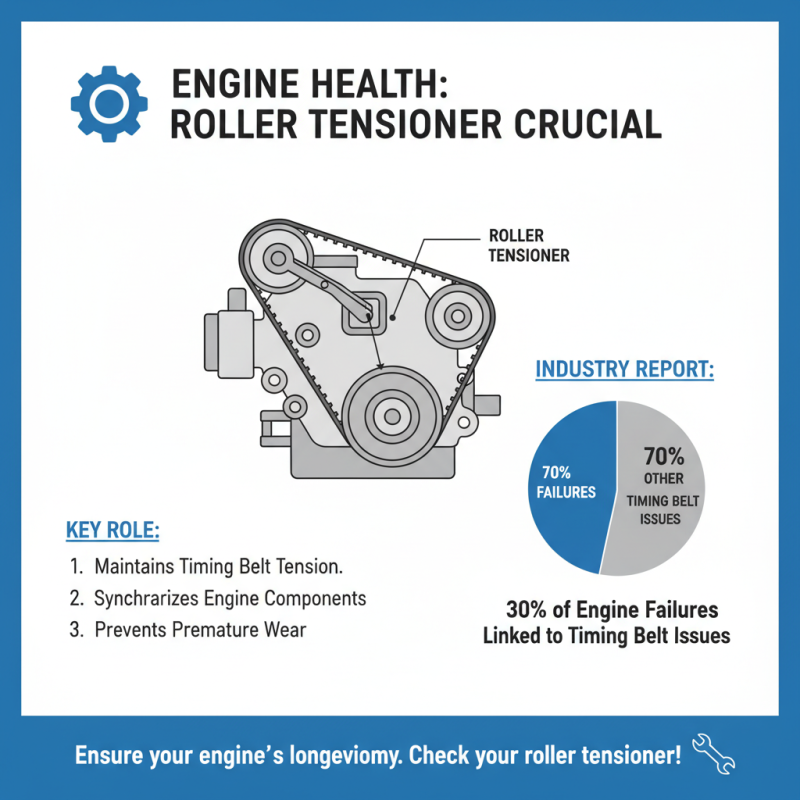

A roller tensioner plays a critical role in engine functionality. It helps maintain the correct tension in the timing belt or chain. This tension is essential for the accurate synchronization of engine components. A well-functioning tensioner can prevent premature wear and potential engine failure. According to a recent industry report, over 30% of engine failures are linked to timing belt issues.

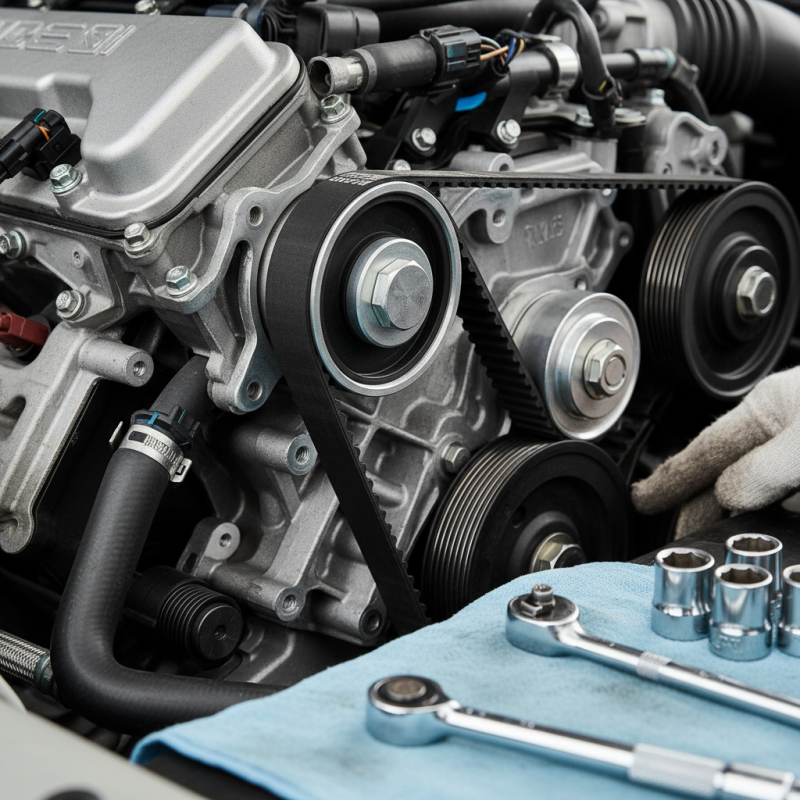

The tensioner works by adjusting the belt's tightness as the engine operates. This adjustment is necessary because belts can stretch or wear down over time. A faulty roller tensioner can lead to increased friction. This friction can escalate heat levels, resulting in further damage. A study showed that vehicles with neglected tensioners had a 40% higher risk of mechanical breakdown.

Routine inspections are crucial. They can identify tensioner wear before it leads to significant issues. Mechanics recommend checking the tensioner during regular maintenance. Many overlook this part, but it can save owners from costly repairs. Recognizing the signs of a failing tensioner can be a game-changer. The difference between a smooth-running engine and a breakdown often hinges on this seemingly small component. Ignoring it can lead to severe consequences.

Maintaining a roller tensioner can significantly enhance your vehicle's longevity. A well-functioning tensioner ensures the correct tension on the timing belt or chain, reducing wear and tear. Studies indicate that a misaligned or worn tensioner can lead to a belt failure in just 50,000 miles. This failure might cause severe engine damage, costing thousands in repairs.

Regular inspections of the roller tensioner provide early detection of potential issues. A report by the Automotive Service Association suggests that 70% of drivers neglect routine maintenance. Ignoring this can lead to decreased engine efficiency and a shorter lifespan for your vehicle. Maintaining proper tension also improves fuel efficiency, which can save you money in the long run.

**Tip:** Check the roller tensioner every 60,000 miles or during oil changes. Listen for unusual noises from the engine, as this might indicate tensioner problems.

Stay aware that not all tensioners will show visible wear, so relying solely on your eyes may not be enough. Mechanics often recommend replacing roller tensioners every 100,000 miles. Delaying this task may cause cascading issues, ultimately leading to costly repairs.

**Tip:** Invest in high-quality replacement parts to protect your vehicle. The upfront cost can prevent larger future expenses. Regular maintenance is crucial for keeping your car running smoothly.

A roller tensioner plays a crucial role in maintaining the proper tension of your vehicle's belts. When it starts to fail, several signs may indicate an issue. Unusual noises, like squealing or grinding, can often be the first alert. If you hear these sounds, it might be time to investigate further. Engine vibrations could also signal a failing tensioner. Pay attention to how your car feels when you drive.

Another noticeable sign is a warning light on your dashboard. This light could indicate problems with the serpentine belt or the tensioner itself. Ignoring it may lead to more extensive damage down the line. Additionally, check for visible wear, such as frayed or cracked belts. These signs suggest that your roller tensioner may not be functioning correctly.

Tips: Regular inspections can help you catch issues early. Listen to your car; sounds can reveal a lot. Don’t wait for severe problems before addressing maintenance. Fix it before it escalates. Remember, a small investment in inspection can save you from expensive repairs later. Keep your vehicle running smoothly. A well-maintained roller tensioner is essential for vehicle health.

Regular inspection and maintenance of a roller tensioner play a crucial role in vehicle performance. A study from the Automotive Maintenance Safety Administration indicates that improper tensioner maintenance accounts for 18% of engine failures. These components tension the timing belt and reduce slippage, ensuring optimal engine operation. A worn-out tensioner can lead to excessive wear on the belt and other engine parts.

To inspect your roller tensioner, look for signs of wear or damage. Check for unusual noises, such as grinding or squeaking, which might indicate a problem. It’s also important to ensure proper tension; a loose belt can lead to inefficiencies or engine misfires. According to industry reports, replacing worn tensioners can increase engine efficiency by up to 30%. It's wise to consult a professional if you're unsure about the condition of your tensioner.

Maintenance requires more than just visual inspections. Regular lubrication is essential for smooth operation. Some vehicle owners overlook this step, leading to premature wear. Remember, prevention is always better than a costly repair down the line. Keeping a detailed maintenance log can help track inspection dates and findings, ensuring you stay on top of your vehicle's health.

The roller tensioner plays a crucial role in your vehicle's engine. It maintains the correct tension on the timing belt or chain. If it fails, the consequences can be severe. An improper tension can lead to slippage, resulting in poor engine performance. A worn-out tensioner may also cause unusual noise, signaling trouble ahead.

When the roller tensioner is not working, it affects the whole system. The timing belt may not rotate correctly, disrupting valve timing. This can lead to decreased power and efficiency. In some cases, you might notice your vehicle stalling unexpectedly. These issues can leave drivers frustrated and in danger on the road.

Ignoring roller tensioner problems can escalate into serious engine damage. Repairs can be costly and time-consuming. Regular maintenance checks can help you catch issues early. It's essential to pay attention to warning signs and act promptly. A well-functioning tensioner ensures smoother rides and better fuel economy. Don't overlook this small but vital component in your vehicle.