In the world of machinery, the importance of a reliable Roller Tensioner cannot be overstated. These components play a crucial role in maintaining optimal performance and efficiency in various applications. When a Roller Tensioner is functioning properly, equipment operates smoothly. However, any failure can lead to significant downtime and costly repairs.

Choosing the right Roller Tensioner is essential. Various models are available, each designed for specific tasks. It's vital to understand the characteristics that make a tensioner effective. Often, users overlook details like load capacity and ease of installation. These factors can greatly influence performance.

Despite their importance, many still don't prioritize regular maintenance. A neglected Roller Tensioner can lead to problems over time. Users must reflect on their maintenance practices. Incorporating the right tensioner can make all the difference. Understanding your options is key to optimizing performance and boosting efficiency.

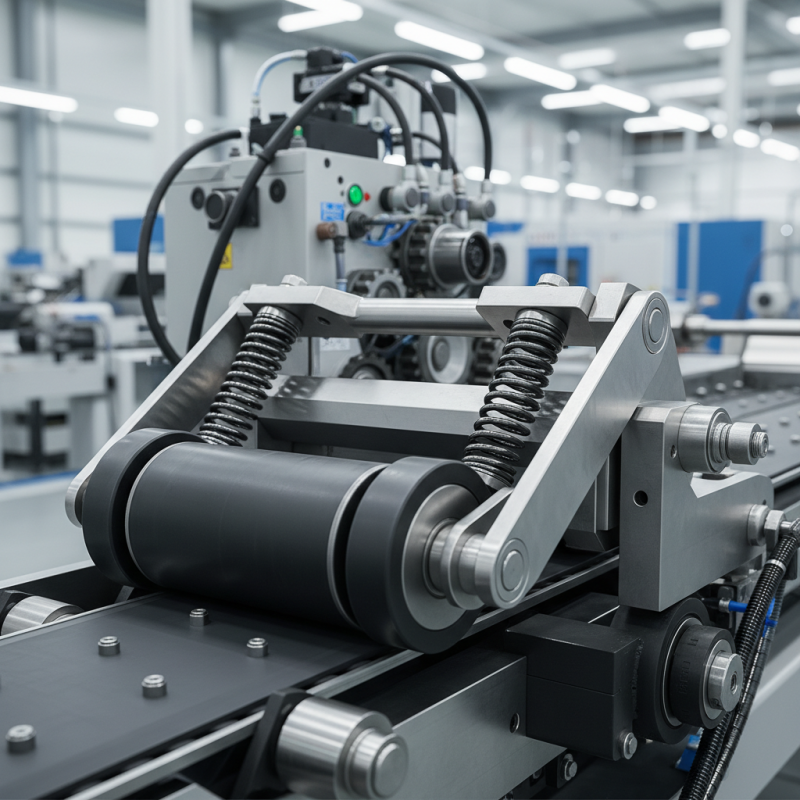

Roller tensioners play a crucial role in various mechanical systems. They adjust the tension in belts and chains to ensure smooth operation. By maintaining proper tension, they prevent slippage and reduce wear. This functionality extends the lifespan of belts, contributing to overall efficiency.

Working principles behind roller tensioners are straightforward yet vital. They often consist of a spring-loaded mechanism. As tension changes, the roller adjusts position automatically. This dynamic action keeps everything running smoothly, even under varying loads. Regular maintenance is necessary to ensure optimal performance.

Tips: Check the condition of your roller tensioners regularly. Look for signs of wear or damage. A worn-out tensioner can lead to premature failure of the entire system. When replacing, make sure to follow installation guidelines. Proper alignment makes a significant difference in functionality.

Keep an eye on noise levels during operation. Unusual sounds may suggest that your tensioner is not functioning correctly. Ignoring these warning signs can lead to costly repairs. It’s easy to overlook such details, but they’re essential for maintaining efficiency. Remember, a well-maintained roller tensioner is key to performance.

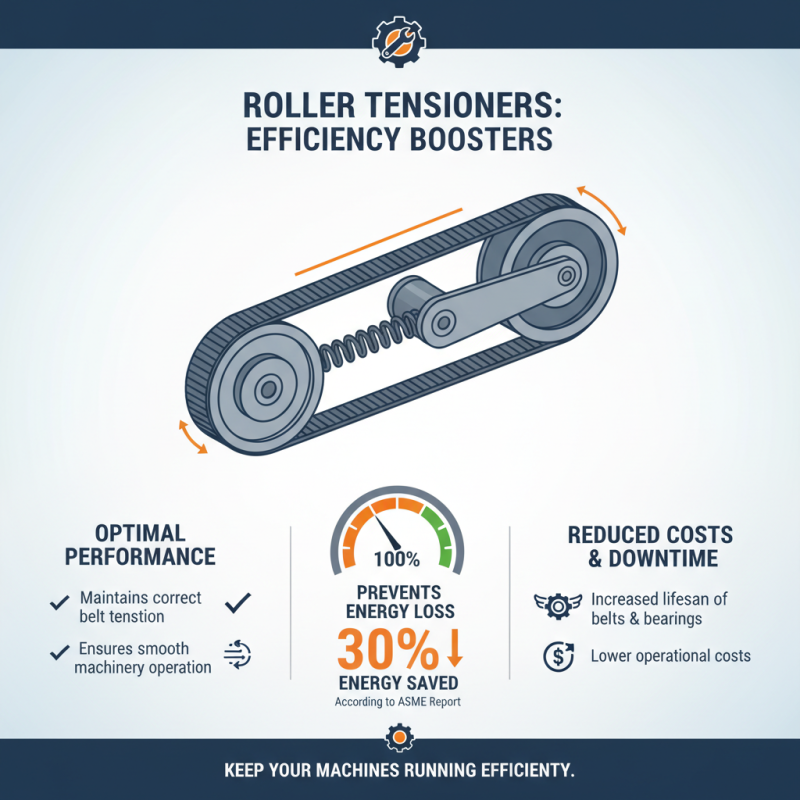

Roller tensioners play a vital role in industrial applications. They keep the drive belts at the right tension. This ensures smooth functioning of machinery. According to a report by the American Society of Mechanical Engineers, improper tension can lead to 30% energy loss. This not only affects efficiency but also increases operational costs.

A well-functioning roller tensioner contributes to the longevity of equipment. Research indicates that machines with correctly tensioned belts can experience a 50% reduction in wear. Smaller, unchecked issues can escalate into costly repairs. Yet, some facilities overlook this aspect. They often underestimate the importance of routine maintenance and assessment.

The variability in manufacturing processes can create unique challenges. Some systems may experience inconsistent belt tension, affecting performance. Regular inspections can prevent these issues. Simple adjustments can lead to significant improvements. A focus on roller tensioners is crucial for achieving optimal performance and efficiency in production lines.

When selecting roller tensioners, consider several critical factors. The material used is paramount. Durable materials resist wear and tear. This directly affects lifespan and performance. Pay attention to the design as well. An ergonomic design allows for easier adjustments and better fit. It minimizes the risk of slippage.

Another aspect is compatibility. Ensure that the tensioner integrates well with your existing system. Mismatched components can lead to inefficiencies. Check reviews and feedback from users. This provides insights into the effectiveness of different models.

Tips: Always test the tensioner before full installation. This helps identify any potential issues early. Regular maintenance is key. Inspect the tensioner routinely for any signs of wear or damage. Small steps can save you from larger problems down the line. Remember, performance can vary based on many factors. Reflect on your choices and their impact on overall operation.

When searching for roller tensioners, several factors must be considered. These components play a crucial role in maintaining optimal performance and efficiency in machinery and conveyor systems. A well-chosen tensioner minimizes wear and tear, ensuring smooth operation. However, not all options are perfect. Some may lack durability under heavy loads, leading to premature failure.

Many products stand out for their unique features. Certain tensioners provide advanced adjustability, allowing for better alignment and performance. This is important, as misalignment can cause significant issues. Additionally, some models offer easy installation, saving time for users. However, a few may require special tools, complicating the setup process.

In terms of maintenance, not all tensioners are created equal. Some might need frequent adjustments, while others maintain tension effectively with minimal intervention. It’s crucial to evaluate what works best for your specific application. A detailed comparison is often a good idea. User reviews can highlight potential shortcomings or unexpected benefits. Users sometimes share their experiences about their chosen tensioners, offering valuable insights that shouldn’t be overlooked.

| Rank | Model | Tension Range (lbs) | Material | Weight (lbs) | Price ($) |

|---|---|---|---|---|---|

| 1 | Model A | 50-150 | Steel | 2.5 | 120 |

| 2 | Model B | 30-120 | Aluminum | 1.8 | 95 |

| 3 | Model C | 40-130 | Plastic | 1.5 | 85 |

| 4 | Model D | 60-180 | Composite | 3.0 | 150 |

| 5 | Model E | 20-100 | Steel | 2.2 | 75 |

| 6 | Model F | 50-170 | Aluminum | 2.8 | 110 |

| 7 | Model G | 35-145 | Plastic | 1.9 | 80 |

| 8 | Model H | 45-155 | Composite | 3.1 | 135 |

| 9 | Model I | 25-115 | Steel | 2.4 | 65 |

| 10 | Model J | 55-165 | Aluminum | 2.7 | 125 |

Maintaining roller tensioners is crucial for optimal performance. Regular inspection is a must. Look for signs of wear or damage. A worn tensioner can lead to poor system efficiency. It may also cause operational issues down the line. Address problems early to prevent bigger headaches later.

Lubrication is key to smooth operation. However, over-lubricating can attract dirt and debris. This buildup can wear out bearings faster. Use a recommended lubricant and apply it sparingly. Check the tension regularly; both too tight and too loose can impact performance negatively. Striking a balance is essential.

Cleaning the tensioner is often overlooked. Dust and grease can accumulate, affecting its functionality. A gentle wipe can make a significant difference. Remember that even minor adjustments or neglect can lead to larger issues. Reflect on your maintenance routine; it’s easy to overlook small details. Stay vigilant!