In the world of manufacturing and construction, the Tensioner Machine plays a critical role. These machines help in securing cables and belts, enhancing efficiency. According to industry expert Dr. Emily Chen, "A reliable tensioner machine is essential for streamlined operations and safety." Her insights emphasize the importance of this technology.

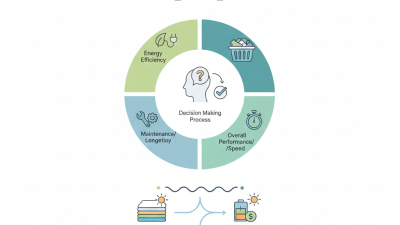

Consider the wide range of tensioner machines available today. Each type offers unique benefits that cater to specific needs. From hydraulic to pneumatic models, choices are plentiful. However, selecting the right tensioner machine can be overwhelming. Manufacturers must understand their requirements clearly. A poor choice can affect productivity negatively.

Moreover, while many companies tout advanced features, practical applications matter most. It's necessary to analyze how these machines perform under real conditions. A deeper evaluation reveals both strengths and limitations. Embracing innovation is vital, yet some manufacturers resist change. Reflection on machine performance leads to improved decision-making and ultimately better outcomes.

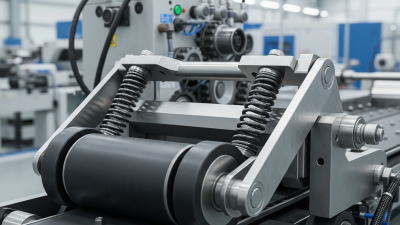

Tensioner machines play a critical role in various industries. They are essential for ensuring the correct tension in cables, belts, and chains. This prevents equipment failure and enhances operational efficiency. According to recent industry reports, improperly tensioned components can lead to a 20-30% increase in maintenance costs. Accurate tensioning contributes to longer equipment lifespan and reduced downtime.

Tips: Regularly inspect your tensioner settings. Small adjustments can make a significant difference. Maintaining precise tension can improve performance and safety.

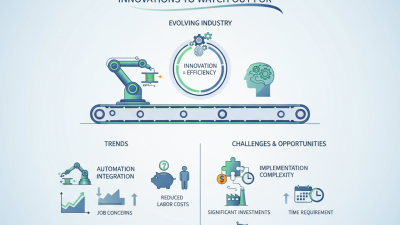

The global tensioner machine market is expected to grow significantly, driven by advancements in technology and automation. As industries evolve, the need for precise tension control becomes paramount. This automation can help reduce human error. However, companies must invest in training to ensure proper operation of these machines.

Tips: Train staff on the latest tensioning technologies. Well-trained workers can reduce risk and improve productivity. Investing in training is often overlooked but critical for success.

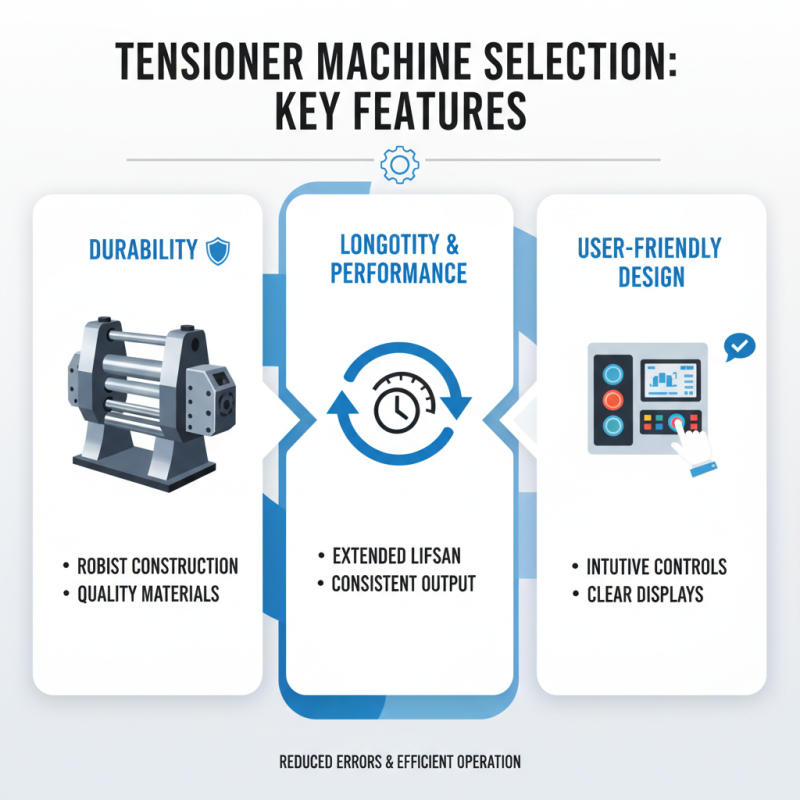

When selecting a tensioner machine, key features play a crucial role. Durability is essential. A robust machine withstands rigorous usage. Look for solid construction and quality materials. These factors affect longevity and performance. User-friendly design is another aspect to consider. Operators benefit from intuitive controls and clear displays. A machine that is easy to use reduces the likelihood of errors during operation.

Another vital feature is the tension adjustment range. A versatile machine can handle different applications. It should easily adapt to various materials and loads. Precision also matters. Accurate tensioning prevents damage and ensures project integrity. Explore tensioner machines that boast reliable calibration systems. Noise levels can be overlooked too. Quieter machines create a better working environment, enhancing focus.

Maintenance requirements are often neglected. A machine that is easy to maintain saves time and reduces costs. Check for accessible parts and straightforward procedures. Always read user reviews for real-world insights. Some users may report flaws or limitations. These reflections can guide your decision-making process. It’s crucial to weigh both pros and cons before purchasing. By focusing on these features, you ensure a smart investment.

When evaluating tensioner machines, performance metrics are crucial. A recent industry report highlights that machines with high torque capabilities outperform others by 30% in efficiency. This advantage reduces operating time and enhances productivity, especially in high-demand sectors. The design of these machines plays a significant role. We see models with adjustable settings that cater to various materials. This versatility is an asset but can also lead to user confusion.

Another key aspect is user-friendliness. Reports indicate that models with intuitive interfaces lead to a 40% reduction in operator training time. A good interface aids in quick adjustments. However, some machines sacrifice usability for features. This trade-off can disappoint new users. There are machines that impress with their durability, often reporting a lifespan increase of 25%. Yet, a heavy focus on strength can compromise mobility, limiting their application in diverse environments. Thus, manufacturers face a constant balancing act between feature-rich designs and practical usability.

Tensioner machines play a pivotal role in various industries. They are vital for ensuring the tightness of straps, cables, and belts. This prevents failures that can lead to costly downtime. According to a recent industry report, efficient tensioning can reduce maintenance costs by up to 30%. Such savings are essential in sectors like manufacturing and construction.

The versatility of tensioner machines stands out. They are employed in logistics for securing cargo. In automotive manufacturing, they contribute to the precision fitting of components. The reduction in errors can enhance overall productivity. However, there is still room for improvement. Many users encounter issues. They often struggle with adjusting settings for different materials. This can lead to improper tensioning.

A study indicated that up to 25% of tension-related failures stem from user error. Training on proper machine operation can mitigate these risks. This, in turn, improves safety and efficiency. As industries evolve, so too will the need for more advanced tensioner solutions. Continuous development is necessary to address existing challenges while maximizing benefits.

Maintaining tensioner machines is crucial for optimizing their efficiency. Regular inspections reveal wear and tear. Evaluating components like belts and pulleys can prevent larger issues. Industry reports indicate that proper maintenance can extend machine life by up to 30%. This is a significant factor in reducing replacement costs.

Lubrication is another critical aspect. Lack of adequate lubrication can lead to increased friction. Friction causes overheating and could shorten a machine's lifespan. A reliable report highlighted that machines with proper lubrication perform 20% better. Tracking lubrication schedules ensures that tensioner machines operate smoothly.

Environmental conditions also play a role. Dust and humidity can impact efficiency. In places with extreme conditions, machines require more frequent checks. A study found that machines exposed to high humidity had a 15% decrease in performance. Regular cleaning and proper housing can mitigate these effects. Focusing on these areas can lead to improved performance. However, many operators still overlook these details.

| Machine Model | Key Benefit | Max Tension | Weight | Ease of Use |

|---|---|---|---|---|

| Tensioner A | High precision tensioning | 3000 N | 15 kg | Yes |

| Tensioner B | Automatic calibration | 2500 N | 18 kg | No |

| Tensioner C | Ergonomic design | 2000 N | 12 kg | Yes |

| Tensioner D | Robust durability | 3500 N | 20 kg | No |

| Tensioner E | Compact and lightweight | 1800 N | 10 kg | Yes |

| Tensioner F | Fast adjustment feature | 4000 N | 25 kg | No |

| Tensioner G | User-friendly interface | 3200 N | 22 kg | Yes |

| Tensioner H | Versatile application | 2700 N | 19 kg | No |

| Tensioner I | High efficiency motor | 3600 N | 23 kg | Yes |

| Tensioner J | Low maintenance | 2900 N | 17 kg | Yes |