Top Cylinder Mould Machine Manufacturers: Product Reviews & Buying Guide

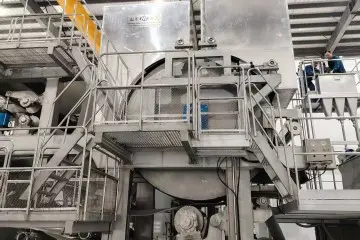

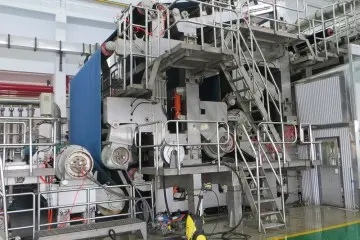

As a trusted supplier of Cylinder Mould Machines, I recognize the critical role quality and reliability play in your manufacturing processes. Our machines, produced by Shandong Haitian Paper Machinery Co., Ltd. in China, are engineered to improve the efficiency of your paper production. Featuring advanced technology, these machines deliver precise forming and superior paper quality. I understand the importance of sourcing from a dependable manufacturer; therefore, our team is dedicated to providing not only exceptional machines but also outstanding service and support throughout your purchasing experience. We take pride in our craftsmanship and innovative design, ensuring our Cylinder Mould Machines are a worthwhile investment for your factory.Ultimate Guide To Cylinder Mould Machine Custom Solutions, Your End-to-End Solution

In the ever-evolving landscape of manufacturing, securing the right solutions for your production needs is crucial. The Cylinder Mould Machine stands out as a cornerstone for those looking to optimize efficiency and quality in their operations. Understanding that each business has unique requirements, customized solutions offer tailored approaches that can significantly enhance performance. By leveraging innovative technologies and applying meticulous attention to detail, you can achieve unmatched results in your production process. A comprehensive, end-to-end solution for Cylinder Mould Machines ensures that every phase—from initial design to final implementation—addresses your specific challenges. This approach not only streamlines the manufacturing process but also elevates product quality and consistency. Collaborating with a partner that emphasizes excellent quality and efficient service will enable you to navigate global markets with confidence, ultimately driving business growth and expanding your reach. As you explore solutions for your business, consider the importance of partnering with a provider that values integrity and innovation. The right Cylinder Mould Machine custom solution can transform your production capabilities, ensuring that you remain competitive in an increasingly demanding industry. Investing in customized machinery tailored to your unique specifications will position your business for long-term success and adaptability in the market.

Ultimate Guide To Cylinder Mould Machine Custom Solutions, Your End-to-End Solution

| Feature | Description | Benefits | Customization Options |

|---|---|---|---|

| Material Type | High-grade stainless steel or carbon steel | Durability and resistance to corrosion | Choice between different alloys |

| Production Capacity | From 100 to 1000 units per day | Flexibility to scale production as needed | Tailored production schedules |

| Machine Size | Compact to large industrial sizes | Space-saving options for small factories | Custom dimensions available |

| Automation Level | Manual, semi-automatic, and fully automatic | Reduced labor costs and increased efficiency | Options for control systems and software |

| After-Sales Support | Comprehensive maintenance and training | Ensures machine longevity and optimal performance | Flexible support packages available |

Discovering Cylinder Mould Machine Global Reach Trusted by Pros

C

Chris Jackson

Impressive durability! The after-sales service provided was exceptional and knowledgeable.

05 June 2025

A

Angela Hall

Great product quality! The team was attentive and supportive throughout the process.

22 May 2025

G

Grace Nelson

Fabulous quality! The after-sales staff went above and beyond to assist me.

13 June 2025

E

Ella Perez

Such reliable performance! The support team was extremely knowledgeable and helpful.

22 May 2025

M

Madison Ward

Amazing quality! The after-sales staff made sure every issue was addressed promptly.

02 July 2025

S

Samantha Parker

Truly impressive quality! Customer support handled my concerns swiftly and professionally.

13 May 2025