Top-Rated Pulp Making Machines from Leading Factories - High-Quality Solutions

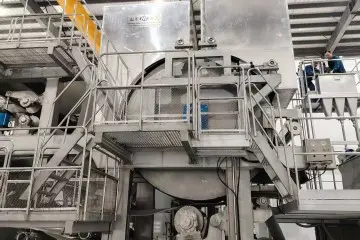

Our Pulp Making Machine is designed for efficient pulp production, ensuring quality and reliability for B2B buyers in the industry. Manufactured in our advanced factory in China, we focus on durability and outstanding performance tailored to diverse paper mill requirements. With cutting-edge technology and expert craftsmanship, we strive to produce machinery that not only meets but surpasses your standards. Our commitment is to elevate your production capabilities, enhance efficiency, and minimize waste. Choosing our Pulp Making Machine means aligning with a trusted supplier focused on your success in the paper sector. Contact us today to find out more about how we can support your business objectives.

Step-by-Step Guide Pulp Making Machine From Concept to Delivery Is The Best

When it comes to the pulp making process, investing in a high-quality Pulp Making Machine is crucial for achieving the desired results. A step-by-step guide can help procurement professionals navigate from concept to delivery, ensuring they select a machine that meets their operational needs while acknowledging various market demands. The journey begins with understanding the production requirements and desired output. This involves a thorough evaluation of the raw materials, processing techniques, and the quality standards expected in the final pulp product. Once the requirements are clearly defined, the next phase involves selecting a manufacturer that embodies a commitment to excellence and innovation. Key factors to consider include the supplier's reputation in both domestic and international contexts, the technology employed in their machines, and their dedication to customer service. A reliable partner not only provides cutting-edge solutions but also ensures efficient communication throughout the entire procurement process. Following the selection, it is essential to oversee the production stages and maintain regular updates on the machine's progress. The delivery phase should also include comprehensive training and support, enabling your team to operate the machinery effectively. By following this structured approach, global purchasers can confidently invest in a Pulp Making Machine that aligns perfectly with their goals, ultimately enhancing productivity and quality in their operations.

Step-by-Step Guide Pulp Making Machine From Concept to Delivery Is The Best

| Step | Description | Timeframe | Key Considerations |

|---|---|---|---|

| 1 | Market Research and Feasibility Study | 2-4 weeks | Identify target markets, analyze competition |

| 2 | Design and Engineering | 4-6 weeks | Incorporate technology and user requirements |

| 3 | Prototype Development | 6-8 weeks | Iterate based on testing and feedback |

| 4 | Production Planning | 3-4 weeks | Supply chain logistics, resource allocation |

| 5 | Manufacturing | 8-12 weeks | Quality control, equipment setup |

| 6 | Testing and Quality Assurance | 2-4 weeks | Ensure compliance with industry standards |

| 7 | Delivery and Installation | 1-2 weeks | On-site setup and demonstration |

| 8 | Training and Support | Ongoing | Provide staff training and technical support |

Methods To choose Pulp Making Machine Service Dominates

S

Sophia Baker

Top quality and performance! The after-sales support is a testament to their commitment to customers.

26 May 2025

W

William Collins

The product quality speaks for itself! The service team was exceptional at problem-solving.

17 June 2025

J

Jacob White

High quality! The professionalism of the after-sales team was outstanding.

22 June 2025

I

Isaiah Hughes

Absolutely love this product! The professionalism of the service staff stood out significantly.

08 June 2025

E

Elena Lane

This product has consistently impressed me with its quality. Support team was incredibly helpful.

23 June 2025

C

Clara Howard

Superior quality and design! The professionalism of their support team left a great impression.

03 June 2025