High-Quality Slitting Cutting Machines | Top Chinese Manufacturers & Factories

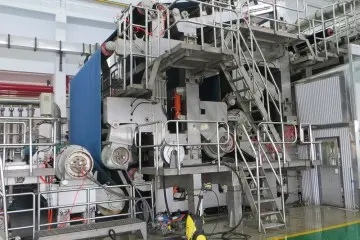

For those seeking a dependable Slitting Cutting Machine, quality and efficiency are paramount. Products from esteemed manufacturers like Shandong Haitian Paper Machinery Co., Ltd. are noteworthy for their ability to enhance productivity through precise cutting across various materials. These machines feature advanced technology and robust design, ensuring durability and ease of use. Ideal for industries such as paper and film, our Slitting Cutting Machines are tailored to meet diverse production needs, ultimately reducing downtime and elevating overall business performance.

Must-See List Slitting Cutting Machine in 2025 Where Innovation Meets 2025

As we step into 2025, the landscape of Slitting Cutting Machines is set for remarkable advancements that cater to the evolving needs of manufacturers worldwide. The must-see list of innovations highlights how these cutting-edge machines are no longer just tools, but integral components of a streamlined production process. With enhanced precision, speed, and adaptability, businesses can boost their operational efficiency while minimizing waste and downtime. Features such as automated adjustments, intuitive controls, and connectivity options are transforming the way slitting operations are managed, ensuring that manufacturers stay competitive in a rapidly changing market. In this era of technological evolution, the demand for Slitting Cutting Machines is driven by a focus on sustainability and resource efficiency. Advanced machinery integrates eco-friendly practices, reducing energy consumption and material waste, which aligns with global trends towards environmental responsibility. Additionally, the incorporation of smart technology enables real-time monitoring and data analytics, empowering businesses to make informed decisions that enhance productivity and profitability. For global buyers seeking reliability and innovation, investing in state-of-the-art slitting machines in 2025 promises to yield significant returns, paving the way for future growth. Moreover, the emphasis on customer-centric service and support has never been greater. As buyers navigate their options in the marketplace, the importance of partnerships that provide not only machinery but also ongoing assistance cannot be overstated. It’s essential to collaborate with manufacturers who prioritize quality and integrity, ensuring that you have the resources needed to maximize the potential of your Slitting Cutting Machines. As the industry evolves, these must-see innovations represent an exciting opportunity for global procurement, ready to meet the dynamic challenges of today and the future.

Must-See List Slitting Cutting Machine in 2025 Where Innovation Meets 2025

| Machine Type | Cutting Width (mm) | Max Speed (m/min) | Power (kW) | Features |

|---|---|---|---|---|

| High-Speed Slitting Machine | 1600 | 300 | 15 | Auto tension control, digital display |

| Precision Slitting Line | 2000 | 250 | 20 | Laser alignment, servo motor drive |

| Smart Slitting Machine | 1200 | 200 | 10 | IoT connectivity, real-time monitoring |

| Compact Slitting Machine | 800 | 150 | 5 | Space-saving design, easy operation |

| Heavy-Duty Slitting Machine | 3000 | 180 | 25 | Robust construction, high durability |

Must-Know Tips For Slitting Cutting Machine Stands Out Application

K

Kevin Brown

Stellar quality! The professionalism of the after-sales team truly made a difference in my purchase.

16 May 2025

D

Daniel Thomas

The reliability of this product gives me confidence in my purchase. Outstanding service after the sale!

14 June 2025

I

Isabella Hernandez

The attention to detail is remarkable. Customer service was professional and made the process easier.

05 July 2025

V

Victoria Scott

Superb quality and reliability! The customer service representatives were well-prepared and informed.

13 May 2025

L

Liam Wood

Exceptional quality! The service team went above and beyond to resolve my concerns.

15 June 2025

Z

Zachary Carter

Really great quality! The professionalism shown by the service staff during my purchase was exemplary.

06 July 2025