Top Thermal Paper Coating Machines in China - High-Quality Manufacturing Solutions

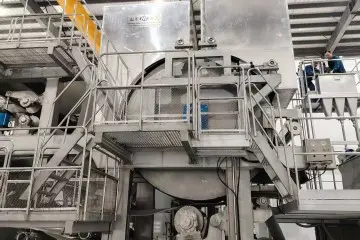

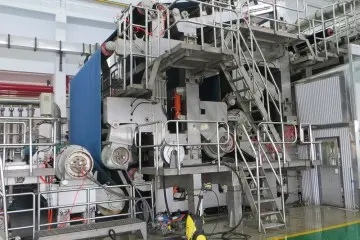

When seeking a reliable **Thermal Paper Coating Machine**, B2B purchasers can trust Shandong Haitian Paper Machinery Co., Ltd. Their machines incorporate advanced technology, ensuring high efficiency and quality throughout the thermal paper production process. Known for their durability and performance, Shandong Haitian tailors its solutions to accommodate both small businesses and larger manufacturers. With a firm commitment to innovation, investing in their **Thermal Paper Coating Machines** guarantees a partnership with an industry leader dedicated to enhancing your production capabilities.Best Ways To Thermal Paper Coating Machine Stands Out From Concept to Delivery

In the competitive landscape of Thermal Paper Coating Machinery, understanding what sets a machine apart is essential for global buyers seeking the best solutions. One of the standout features of advanced Thermal Paper Coating Machines is their ability to integrate innovative technology with high-quality manufacturing processes. These machines not only enhance efficiency but also ensure exceptional output consistency. By employing state-of-the-art technology, manufacturers can create machines that optimize coating thickness and adhere to strict quality standards, addressing the dynamic needs of the market. Moreover, the delivery process of these machines has evolved to ensure that clients receive tailored solutions that meet their specific requirements. This is achieved through comprehensive consultations and customizations that enable manufacturers to understand the unique demands of each client, from small businesses to large-scale enterprises. By focusing on efficient service delivery and timely follow-ups, companies can forge long-lasting relationships with their clients, fostering trust and reliability. Ultimately, investing in the right Thermal Paper Coating Machine involves more than just a transaction; it’s about partnering with a provider that prioritizes quality, innovation, and customer satisfaction. As global procurement professionals evaluate their options, understanding these key differentiators will help them make informed choices that drive their businesses forward.

Best Ways To Thermal Paper Coating Machine Stands Out From Concept to Delivery

| Feature | Description | Benefits | Application |

|---|---|---|---|

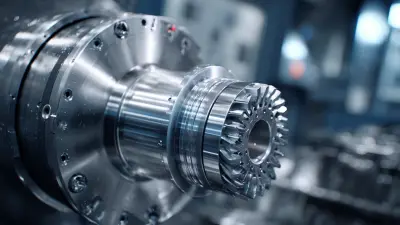

| High Precision Coating | Advanced technology ensures uniform coating thickness. | Improved print quality and reduced paper waste. | Retail and logistics for barcode labels. |

| Versatile Material Compatibility | Compatible with various paper types and coatings. | Flexible production for different client needs. | Hospital and pharmacy labels. |

| Energy Efficient | Designed to minimize energy consumption. | Cost savings and lower environmental impact. | Various industrial applications. |

| User-Friendly Interface | Intuitive controls for easy operation. | Reduced training time for operators. | Small and medium-sized printing houses. |

| Robust Construction | Durable design for extended machine life. | Lower maintenance costs and increased uptime. | Heavy-duty industrial use. |

Proven Methods To Thermal Paper Coating Machine Trusted by Pros Industry Leaders

D

Daniel Thomas

The reliability of this product gives me confidence in my purchase. Outstanding service after the sale!

14 June 2025

M

Megan Davis

High-quality materials used! The support team was not only responsive but extremely professional.

06 June 2025

C

Chris Jackson

Impressive durability! The after-sales service provided was exceptional and knowledgeable.

05 June 2025

M

Madison Ward

Amazing quality! The after-sales staff made sure every issue was addressed promptly.

02 July 2025

D

Daniel Ramirez

A standout product in quality! The service team was quick and professional.

17 May 2025

E

Eli Turner

High-quality product! Their support team was exceptionally professional and courteous.

22 June 2025