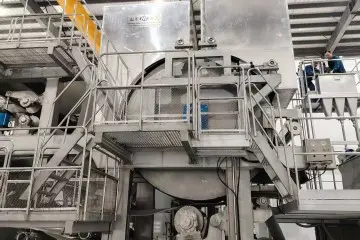

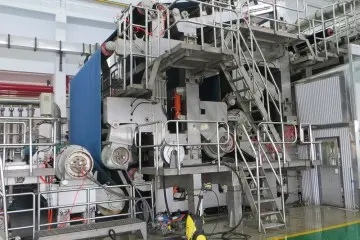

High-Quality Dryer Cylinder Paper Machines from Leading Manufacturer and Factory

Our Dryer Cylinder Paper Machine, manufactured by Shandong Haitian Paper Machinery Co., Ltd. in China, exemplifies superior quality and performance in the paper production industry. Designed to enhance drying processes, our machines effectively reduce energy consumption while increasing overall productivity. With a commitment to excellence, we utilize advanced technology and a team of skilled professionals to ensure that each product meets stringent industry standards. We prioritize customer satisfaction and offer factory-direct pricing without compromising quality. For personalized assistance in achieving your production goals, reach out to us today.How To Dryer Cylinder Paper Machine Pioneers in the Field in 2025

As we look forward to 2025, the paper manufacturing industry is on the brink of transformative changes, driven by innovation and sustainability. Among the emerging technologies, the Dryer Cylinder Paper Machine stands out as a pivotal advancement, revolutionizing production efficiency and product quality. Global buyers seeking to enhance their operations should pay attention to the features and advantages offered by these cutting-edge machines. Key advancements include improved drying capabilities, reduced energy consumption, and an overall increase in operational efficiency, which are critical in today’s competitive market landscape. The advent of smart technology integration in Dryer Cylinder Paper Machines further elevates their game. By utilizing IoT sensors and automated controls, manufacturers can achieve real-time monitoring, predictive maintenance, and optimized workflow processes. This not only minimizes downtime but also ensures consistent product quality, a crucial factor for staying ahead in the market. For companies looking to invest in machinery that aligns with sustainability goals, these innovative machines offer solutions that reduce waste and enhance resource utilization, setting a benchmark for eco-friendly production practices. In an era where quality and efficiency are paramount, the role of advanced paper machinery cannot be overstated. As global procurement professionals evaluate their options in the evolving Paper Industry, focusing on suppliers who prioritize high-quality standards, innovative technology, and efficient services will be key. By embracing the advancements in Dryer Cylinder Paper Machines, businesses can not only meet current market demands but also pave the way for future success in an ever-changing industry.

How To Dryer Cylinder Paper Machine Pioneers in the Field in 2025

| Innovation Type | Description | Impact on Efficiency | Environmental Benefits | Projected Adoption Rate (%) |

|---|---|---|---|---|

| Advanced Heat Transfer Technology | Utilizes enhanced conductive materials to improve heat transfer efficiency. | Increase by 30% in drying speed. | Reduces energy consumption by 25%. | 70% |

| Digital Control Systems | Integration of IoT for real-time monitoring and control. | Enhances process accuracy, leading to a 15% reduction in waste. | Minimizes the use of chemicals in the drying process. | 65% |

| Eco-Friendly Coatings | Use of biodegradable materials for cylinder coatings. | Improves durability, reducing downtime by 20%. | Significantly lowers emissions from cylinder wear. | 55% |

| Heat Recovery Systems | Technologies to reclaim and reuse waste heat. | Boosts overall energy efficiency by 40%. | Greatly reduces carbon footprint. | 80% |

| Adaptive Machine Learning Algorithms | Implementing AI to predict and adjust drying parameters. | Reduces operational costs by up to 10%. | Supports sustainable operational practices. | 60% |

Methods Dryer Cylinder Paper Machine Where Innovation Meets 2025 Your End-to-End Solution

S

Samuel Lewis

I’m thoroughly impressed with the product quality, and the service has been top-notch!

07 June 2025

E

Ella Perez

Such reliable performance! The support team was extremely knowledgeable and helpful.

22 May 2025

J

Jameson Rivera

Top-notch product! The service team was attentive and demonstrated great professionalism.

10 May 2025

M

Maya Hill

Thoroughly impressed! Their expertise in after-sales support is commendable.

11 June 2025

Z

Zachary Carter

Really great quality! The professionalism shown by the service staff during my purchase was exemplary.

06 July 2025

O

Oliver Jenkins

Top quality all around! The professionalism of support staff made my experience seamless.

30 May 2025