Top China Paper Mill Pulper Manufacturer | High-Quality Factory Products

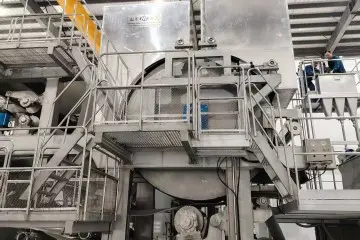

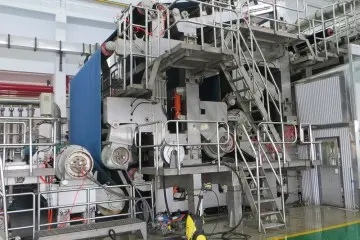

If you seek a dependable and high-quality Paper Mill Pulper, our offerings are crafted by experienced manufacturers to meet the needs of modern paper production. Utilizing innovative technology and robust engineering, our pulpers effectively break down raw materials, ensuring optimal performance and longevity. At Shandong Haitian Paper Machinery Co., Ltd., we prioritize quality and customer satisfaction. Our solutions not only enhance productivity but also help reduce operational costs. Whether expanding your production line or upgrading existing machinery, our Paper Mill Pulpers are designed for diverse applications. Our dedicated team is ready to assist you throughout the purchasing process, addressing any questions and providing necessary support. By choosing our high-quality pulpers, you are ensuring reliability and excellence in the paper manufacturing sector. Together, let's enhance your production capabilities!

Quick Tips To Paper Mill Pulper Dominates Application

When it comes to optimizing the efficiency of Paper Mills, understanding the crucial role of pulpers is essential. These machines are the backbone of the recycling process, transforming raw waste material into reusable pulp. To ensure that your operations run smoothly, consider implementing these quick tips to maximize the effectiveness of your pulper applications. First, choose the right type of pulper that aligns with your production needs. There are various designs available, including gravity, drum, and hydropulpers, each tailored for specific types of waste material. Conducting a thorough analysis of your input materials will help in selecting the ideal machine. Additionally, regular maintenance is key. Establishing a routine check-up schedule can prevent unexpected breakdowns and prolong the life of your pulper, ensuring high operational efficiency. Finally, investing in innovative technology can significantly enhance your pulping processes. Modern pulpers come equipped with advanced features that improve energy efficiency and reduce downtime. By staying abreast of the latest developments in pulping technology, you can position your mill to not only meet current demands but also adapt to future challenges in the industry. Embracing these practices will lead to improved productivity and lower operational costs, making your paper production process as competitive as possible in the global market.

Quick Tips To Paper Mill Pulper Dominates Application

| Tip | Description | Benefit |

|---|---|---|

| Regular Maintenance | Perform regular checks and maintenance on pulpers to ensure smooth operation. | Increases the lifespan of equipment and reduces downtime. |

| Optimize Pulping Process | Adjust the settings for temperature, chemical concentration, and time. | Improves efficiency and pulp quality. |

| Employee Training | Provide continuous training for operators on equipment usage. | Enhances safety and operational effectiveness. |

| Monitor Raw Material Quality | Check the quality of raw materials before processing. | Ensures high pulp quality and reduces waste. |

| Implement Eco-Friendly Practices | Adopt sustainable practices in sourcing and processing materials. | Reduces environmental impact and promotes corporate responsibility. |

Methods To choose Paper Mill Pulper Your End-to-End Solution Trusted by Pros

E

Ethan Allen

I’m quite satisfied with my purchase. The service team was incredibly supportive and responsive.

28 June 2025

Z

Zoe Rogers

Fantastic quality! Their after-sales service team was quick to respond and very knowledgeable.

30 May 2025

L

Liam Wood

Exceptional quality! The service team went above and beyond to resolve my concerns.

15 June 2025

N

Nathan Hill

A quality product that impresses! Support staff were responsive and knowledgeable.

16 June 2025

S

Samantha Parker

Truly impressive quality! Customer support handled my concerns swiftly and professionally.

13 May 2025

J

Jack Lopez

Not only is the quality fantastic, but the support staff also provided exceptional service!

08 July 2025