Top Manufacturers of Outstanding Pulp and Paper Making Products for Quality Production

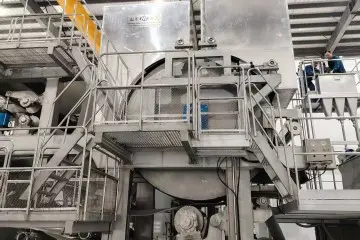

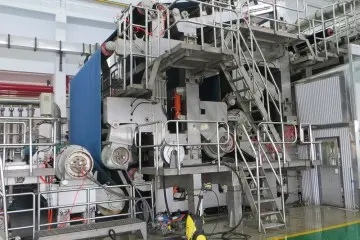

As an experienced player in the pulp and paper making industry, we recognize the crucial role of selecting the right machinery for optimal production. At Shandong Haitian Paper Machinery Co., Ltd., our innovative solutions are crafted specifically for factories and manufacturers seeking top-tier equipment. We offer advanced technology that enhances efficiency while minimizing waste, enabling you to meet rising production demands seamlessly. Whether you're a seasoned manufacturer or newly entering the Pulp and Paper Making Process, our customized machinery solutions significantly enhance your output. Renowned for our reliability and quality, we empower clients to achieve their production objectives without sacrificing performance. Rely on us for superior machinery that complies with international standards and supports sustainable practices, allowing your factory's capabilities to reach new heights.Practical Strategies for Pulp And Paper Making Manufacturer Products

In the competitive world of Pulp And Paper manufacturing, global buyers are increasingly seeking suppliers who not only provide high-quality products but also offer innovative solutions and reliable services. To meet these demands, manufacturers must embrace practical strategies that enhance their product offerings and operational efficiencies. One effective approach is the adoption of advanced technologies that streamline production processes and improve product quality. By investing in state-of-the-art machinery and automation, manufacturers can reduce waste, lower costs, and ensure consistent performance across their product lines. Furthermore, establishing a robust supply chain is critical for timely delivery and responsiveness to customer needs. Collaborating with reliable suppliers and logistics partners enables manufacturers to optimize inventory management and enhance distribution efficiency. This agility not only satisfies buyer demands but also builds trust and long-term relationships in the market. Additionally, implementing a strong focus on sustainability can be a significant differentiator. By integrating eco-friendly practices into operations, manufacturers can appeal to environmentally conscious consumers and comply with increasing regulatory standards. Finally, providing exceptional customer service is paramount. Engaging with clients through personalized support, timely communication, and after-sales service can significantly enhance customer satisfaction and loyalty. By prioritizing integrity and transparency in all dealings, manufacturers can foster a reputation based on trust, ultimately leading to increased market share and sustained growth in both domestic and international arenas.

Practical Strategies for Pulp And Paper Making Manufacturer Products

| Product Type | Raw Materials | Production Process | Sustainability Practices | Quality Control Measures |

|---|---|---|---|---|

| Writing Paper | Wood pulp, fillers, sizing agents | Cooking, bleaching, refining, drying | Use of recycled paper, energy-efficient processes | Regular testing for brightness and opacity |

| Cardboard | Recycled paper, wood chips | Pulping, forming, pressing, drying | Utilization of post-consumer waste | Strength testing and thickness measurement |

| Newsprint | Wood pulp, recycled fibers | Pulping, pressing, drying, cutting | Minimized water usage, recycling of process water | Color stability and printability tests |

| Tissue Paper | Pulp (virgin or recycled), softening agents | Sheet forming, drying, softening | Sourcing from sustainably managed forests | Absorbency and softness testing |

Top-Rated Pulp And Paper Making From Concept to Delivery Supplies the World’s Top Brands

S

Sarah Martinez

The attention to detail in the product is commendable. The customer support was friendly and efficient.

16 May 2025

S

Samantha Torres

Impressive durability! The service provided after my purchase was fantastic.

02 June 2025

J

Jameson Rivera

Top-notch product! The service team was attentive and demonstrated great professionalism.

10 May 2025

N

Nora Foster

Simply excellent! The professionalism of the after-sales service sets them apart.

22 June 2025

M

Maya Hill

Thoroughly impressed! Their expertise in after-sales support is commendable.

11 June 2025

M

Maya Brooks

The craftsmanship is excellent. The responsive and professional service team made my experience even better.

17 June 2025