Premium China Paper Roll Slitting & Rewinding Machines - Reliable Manufacturers & Products

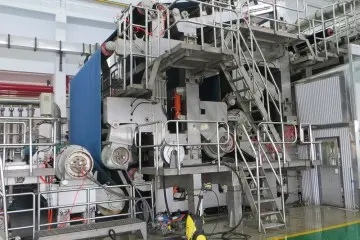

Optimize your production line with our premium Paper Roll Slitting & Rewinding Machine, specifically tailored for the paper industry. Engineered with advanced technology and precision, this machine delivers efficient slitting and rewinding for a variety of paper types. With years of experience, Shandong Haitian Paper Machinery Co., Ltd. is committed to customer satisfaction and product quality. Each machine undergoes rigorous quality control in our factory, ensuring exceptional durability and performance. Enhance your production capabilities, reduce waste, and boost output with our reliable equipment. Our dedicated team is ready to help you find the perfect solution for your needs. Partner with us to elevate your operations.Tips & Tricks for Paper Roll Slitting & Rewinding Machine Your End-to-End Solution Supplier

When it comes to maximizing the efficiency and quality of your paper roll slitting and rewinding operations, having the right equipment is crucial. A reliable slitting and rewinding machine not only enhances production speed but also ensures precision in cutting, which is essential for meeting global market demands. Whether you are dealing with various paper types or different roll sizes, understanding the key features and technologies can significantly improve your output. Look for machines that incorporate innovative technology, allowing for quick changeovers and easy operation, minimizing downtime and maximizing throughput. Moreover, optimizing your machine's performance requires regular maintenance and proper setup. Training your operators on best practices and operational efficiency can lead to significant gains. Utilize automation features where possible to reduce manual intervention, which enhances precision and consistency in the slitting process. Engaging with a supplier who offers comprehensive solutions—including machine installation, operator training, and ongoing support—ensures you have the resources needed for long-term success in a competitive market. In addition to equipment efficiency, maintaining strong supplier relationships is vital. A first-class supplier not only provides high-quality machines but also understands your unique needs and can adapt solutions accordingly. Prioritize suppliers who are known for their commitment to integrity and customer service, ensuring that you have a partnership that supports your operational goals and helps you navigate the complexities of the global Paper Industry. By focusing on these tips and leveraging the right partnerships, you can enhance your production capabilities and stay ahead in the market.

Tips & Tricks for Paper Roll Slitting & Rewinding Machine

| Tip/Trick | Description | Benefits | Frequency |

|---|---|---|---|

| Regular Maintenance | Schedule periodic checks and servicing of the machine. | Increased lifespan and reduced downtime. | Monthly |

| Proper Alignment | Ensure that the slitting blades are correctly aligned. | Improved cut quality and reduced material waste. | Before each run |

| Use Quality Materials | Select high-quality paper and components for the machine. | Enhanced productivity and superior finished products. | Ongoing |

| Operator Training | Provide thorough training for machine operators. | Increased efficiency and safety. | As needed |

| Monitor Performance | Track machine performance metrics regularly. | Identify issues early and optimize processes. | Weekly |

Curated Selection of Paper Roll Slitting & Rewinding Machine in 2025 Dominates

J

James Thompson

The quality of the product exceeded my expectations. The support team was proactive and extremely knowledgeable.

11 May 2025

M

Madison Ward

Amazing quality! The after-sales staff made sure every issue was addressed promptly.

02 July 2025

L

Layla Bennett

The durability is fantastic! Customer support has been nothing short of outstanding.

10 June 2025

N

Nora Foster

Simply excellent! The professionalism of the after-sales service sets them apart.

22 June 2025

M

Maya Hill

Thoroughly impressed! Their expertise in after-sales support is commendable.

11 June 2025

B

Brayden Clark

A product that performs well! The after-sales service was very responsive and professional.

25 June 2025